Design Engineer need to perform their own simulations?

It makes them a better designer, analyzing their own designs while they are still in the form of easily modifiable CAD models to allow for quick turnaround times, reducing product development time and cost.

SimSolid is the game-changing simulation technology for designers, and for Engineers having No background in Analysis related software and analysts, it is very easy to learn & get results in seconds to minutes, it is really fast. Hence, multiple design scenarios can be quickly analyzed and compared.

It is a structural Simulation tool that operates on Original, Un-simplified CAD Geometry

The Geometry simplification – a Time consuming Process

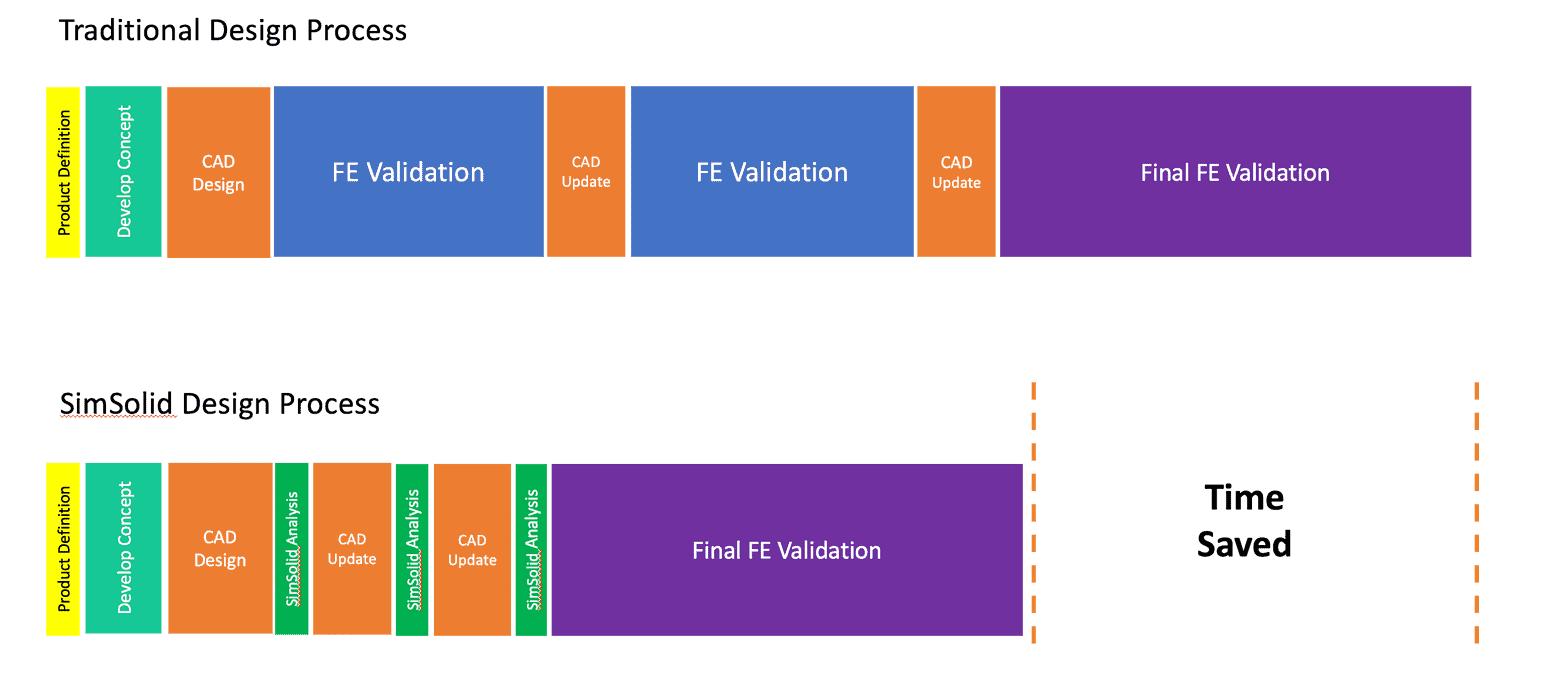

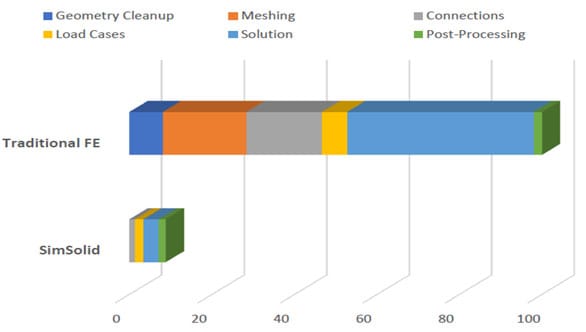

The geometry of CAD and traditional FEA are different. CAD creates geometry to define design and manufacturing requirements, while FEA needs to transform this into a simplified form to define the mesh. This disparity between CAD and FEA geometry models needlessly complicates the analysis-user paradigm in many areas.

Here is an example of the original CAD geometry and one possible simplification used in traditional FEA.

With SimSolid, all features are left in the model and the full fidelity geometry is used in the analysis. This geometry is a complex single part of 1,200+ faces and 150+ small holes. Solution time including model setup is less than four minutes, and reanalysis is fast—less than one minute.

Simulation working directly on design geometry provides a path to quick meaningful answers that guide designers and engineers for more optimal design scenarios. Only SimSolid eliminates Geometry simplifications techniques such as Defeaturing & mid-planning and also Meshing time all together.

Benefits :

● No meshing Involved. So significant time savings

● Analysis run time typically finishes in seconds or minutes!

● Complex Assemblies can be easily analyzed.

● Multiple Designs can be evaluated simultaneously.

Customers in Manufacturing, Medical, Architecture, Automotive, Aerospace, & other industries immensely benefit from SimSolid. Some of the success stories are given below:

1. Andron Handling, (UK)

Andron Handling needed to assess the strength of the welded fabrication and vertical clamping arms for both lifting and clamping loads. In previous analysis of this type in Altair SimSolid™, they would have removed the wheels from the model and applied reaction forces at the bottom of each of the clamp arms. In this case, Andron used a different approach that would not have been possible with previous FEA toolsets.

|

2.Prosthesis Lab Dalboon

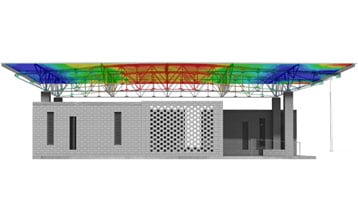

To build a very simple, robust, sustainable roof structure for a prosthesis lab associated with the Centre medico-chirurgical de l'Ulcère de Buruli, which is a hospital in Bouaké, on the Ivory Coast of Africa, the project team used Altair SimSolid, to conduct very fast, full assembly tests, saving time and money, while providing increased flexibility, without compromising accuracy.

|

3. Roth McFarlane London, Ontario

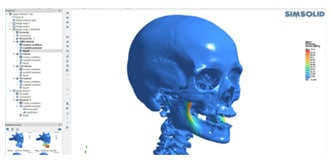

See how McFarlane Hand and Upper Limb Centre in London, Ontario is uses Altair SimSolid™ to evaluate the biomechanics of bone stresses.

|

4. Serapid

Serapid, the developer and manufacturer of the original Rigid Chain, designs and manufactures telescopic mechanical actuators for the horizontal and vertical movement of heavy loads. See how they use Altair SimSolid™ to aid in gravity loads of complete structure simulation.

|

The author, Angayar Kanni T Business Development Engineer drive global strategy for engineering solutions at APA Engineering.

she can be reached at kanni.t@apaengineering.com, Contact Number: +91-9047781140

Banner Picture Courtesy – Altair

Article Reference – Altair

If you would like to know more about this topic.