Why Us?

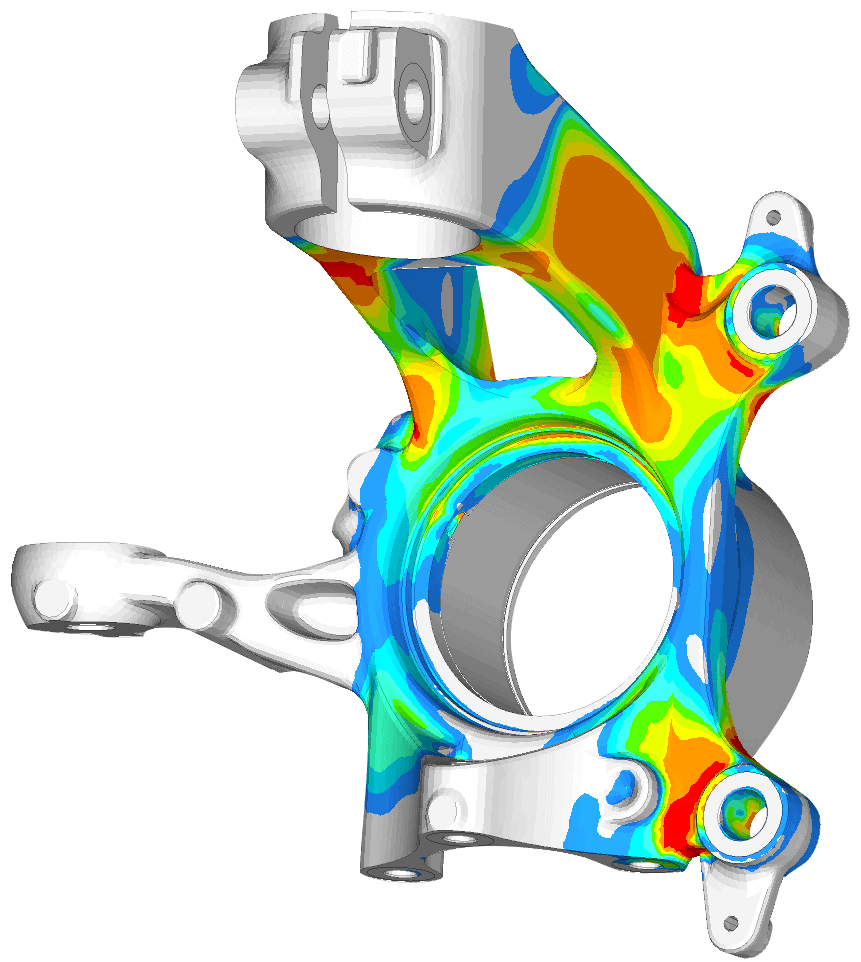

Finite Element Analysis (FEA)

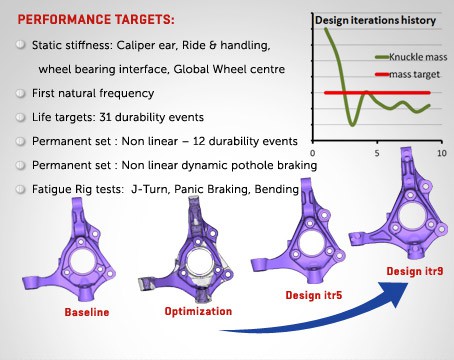

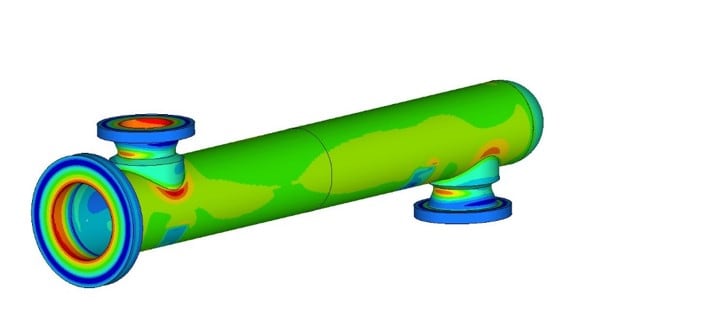

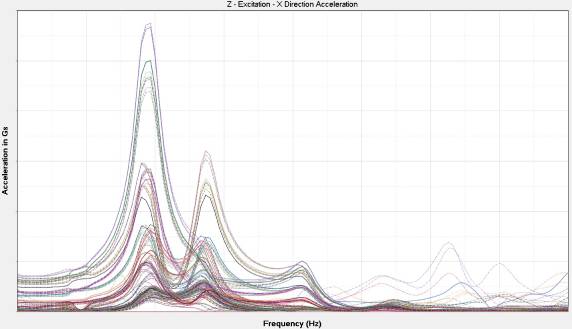

Finite Element Analysis (FEA) is one of the most efficient virtual simulation processes, to predict how a product reacts to external real-world loads. FEA approach helps to determine the weaker sections and modify the design to achieve the desired performance under durability, vibration, thermal and impact loading conditions. Thus, significantly reducing the product development time and cost of prototypes.

Our team has extensive experience in finite element analysis of complex industrial products, automotive components that are exposed to different static, dynamic, thermal and impact loads. In response to these loads, hot spot regions are traced out and effective root cause analysis for the failure are cracked down, which is important to obtain an improved design. We can also generate an innovative concept design proposal by using Topology, shape & Size, optimization techniques to obtain structure meeting all desired performance targets within a given package space. Thus, with FEA driven design development process, we could help our clients make decisions about product design during any stage of product development, cost efficiently.

Skill Set

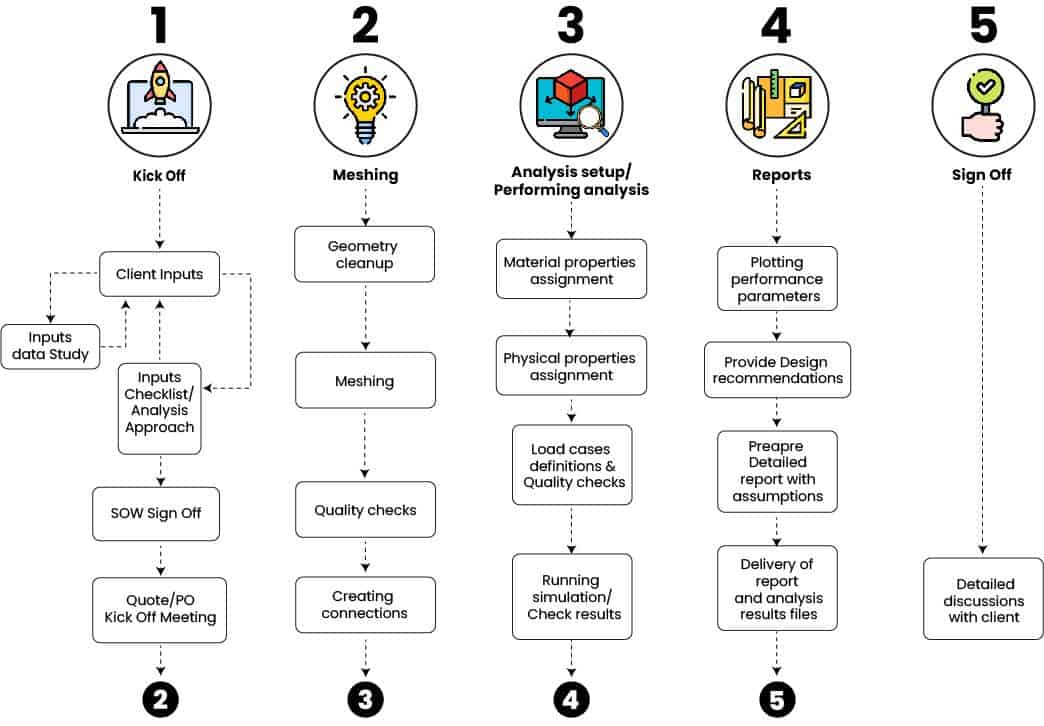

Flow Chart

Talk to our expert

FEA Case Studies

Don't have much time to go through?

30 seconds is all you need.