If your focus is to create high quality Castings & increase your profits, then Altair Inspire Cast software is the one, your team must have.

It is the only tool that caters to beginners and experts alike, from product designers to foundry engineers.

Visualizing casting defects such as air entrapment, shrinkage porosity, cold shuts, or mold degradation is very Easy, Quick, accurate, and affordable. and it also rectifies them avoiding costly downstream corrections.

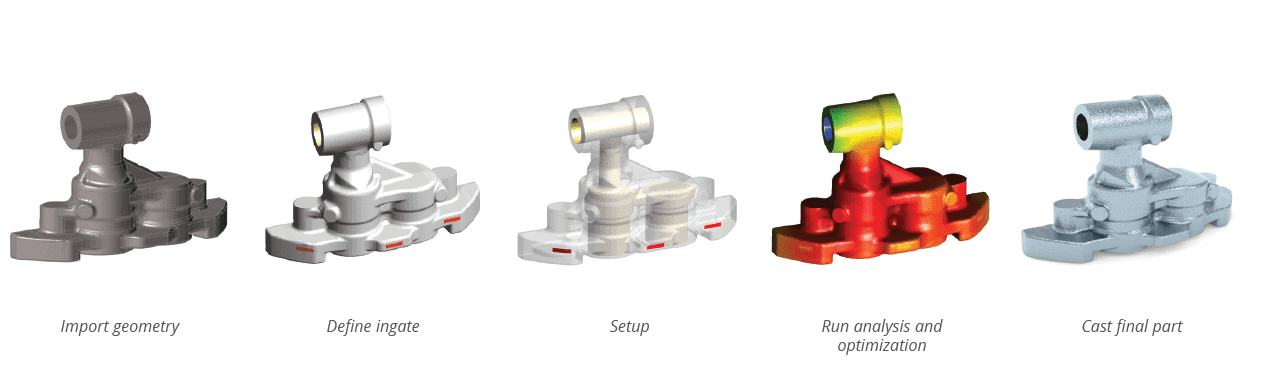

With just few hours of training, engineers can use the Guided process templates offering five easy steps to simulate gravity die, gravity sand, investment, high pressure, low pressure die casting, and tilt pouring.

Benefits of Altair Inspire Cast Software:

Design Better Products:

● Quickly evaluate ‘Castability’

● Visualize solidification to optimize ingate location

● Simulate casting with auto-generation of risers

● Guide manufacturing engineers to refine process

Increase Manufacturing Quality and Profitability:

● Quickly evaluate casting complexity for quoting

● Predict common casting defects upfront

● Optimize running and feeding systems

● Avoid expensive trial and error

Customer Success Story: Woodland/Alloy Casting Inc

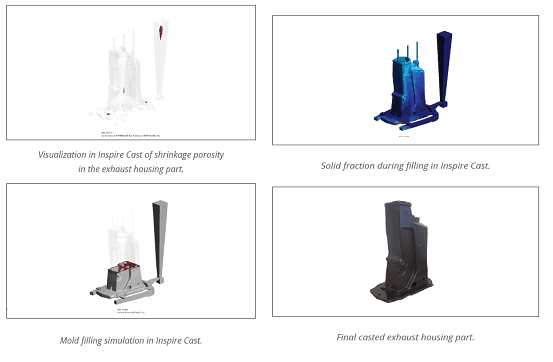

Challenge: Transitioning a marine exhaust housing part from a lost foam casting to a sand casting.

They had to produce a sound casting, while still keeping ingates and risers to a minimum, this would allow for the yield to remain low and help reduce the time needed to remove the rigging.

In order to create this sand casting, a new gating system was designed that would feed the casting from the bottom flange and push the metal to the top of the casting. Once the updated design was finalized, Woodland/Alloy Casting tested the new gating system by running a simulation in Inspire Cast. Woodland/Alloy Casting was able to conclude that the new gating system would produce a casting with zero defects. Before utilizing Inspire Cast, Woodland/Alloy Casting would have conducted numerous costly and time consuming tests, requiring a number of molds to determine the outcome of the new gating system.

The author, Angayar Kanni T Business Development Engineer drive global strategy for engineering solutions at APA Engineering.

she can be reached at kanni.t@apaengineering.com, Contact Number: +91-9047781140

Banner Picture Courtesy – Altair

Content Courtesy: – Altair Engineering

If you would like to know more about this topic.