Forming simulation enables the fast review of several alternative concepts for quality and cost improvements, which results in huge cost and time savings. The number of tool tryouts is reduced, and tryout time is shortened, ultimately leading to highest part quality.

Altair Inspire form helps to:

● Design better products with early check for forming feasibility

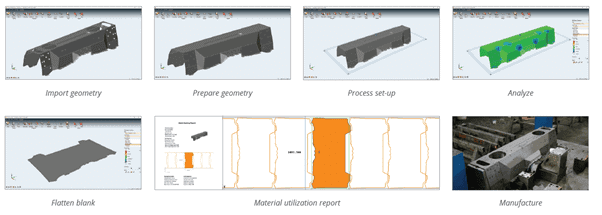

● Reduce scraps and improve material utilization

● Improve productivity with accurate formability analysis

● Optimize the process through single and multi-stage virtual tryout

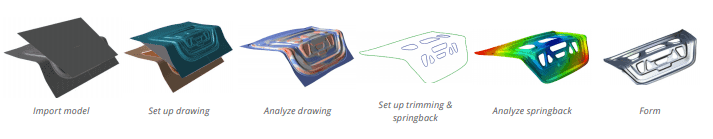

Highly simplified tryout workflow as shown below.

Benefits:

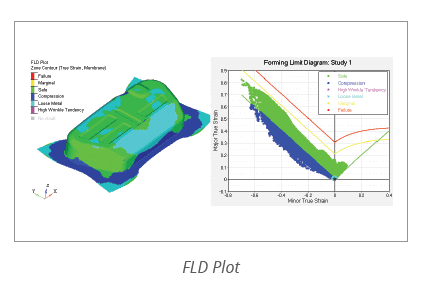

● Identify potential stamping defects such as splits and wrinkles and modify product design early in the design cycle.

● User-friendly interface suitable for both Design Engineers & Process Engineers

● Quick and optimal nesting of blank in the sheet metal coil to maximize material utilization for progressive and transfer die forming

● Assist die face designers to identify process conditions like blank holder force, draw bead location, and draw bead force before detailed incremental analysis

Inspire form Workflow:

Customer story: Pragati Engineering

Challenge is to reduce development time, cost and to remove cracks and wrinkle formation in their products.

Because the team earlier used their traditional method of trial and error, they were unable to predict these occurrences, had to do die corrections manually and rebuild a new tool.

After using Inspire form, the team was able to find out instances of failure, wrinkles, or cracks in sheet metal panel components right at the design stage. This drastically reduced the number of physical trials, thereby achieving highly accurate and speedy results during product development cycle.

For more details:Click Here

The author, Angayar Kanni T Business Development Engineer drive global strategy for engineering solutions at APA Engineering.

she can be reached at kanni.t@apaengineering.com, Contact Number: +91-9047781140

Banner Picture Courtesy – Altair

Content Courtesy – Altair Engineering

If you would like to know more about this topic.