Why Choose APA Engineering?

Our deep domain expertise in thermal and flow simulations helps OEMs optimize cabin comfort, HVAC design, and defrosting performance—reducing prototyping costs and improving product reliability.

Project Objective

The objective of this project was to analyze and enhance the HVAC performance inside a truck cabin using steady-state CFD simulations. The key goals included:

- ✔ Uniform airflow and temperature distribution for driver comfort

- ✔ Effective window de-icing and defogging

- ✔ Air velocity through newly added louvers

Scope of Work

APA Engineering carried out a comprehensive CFD analysis using CFD tools, focusing on improving cabin airflow and comfort.

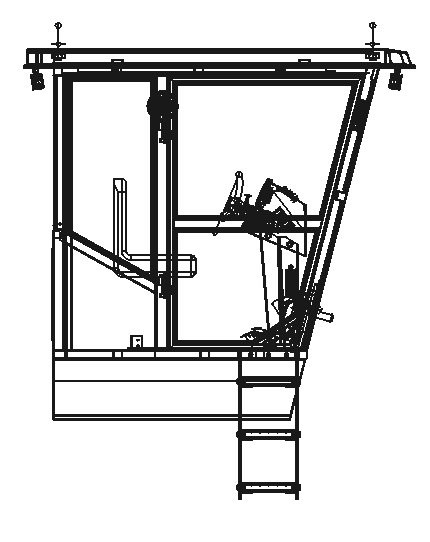

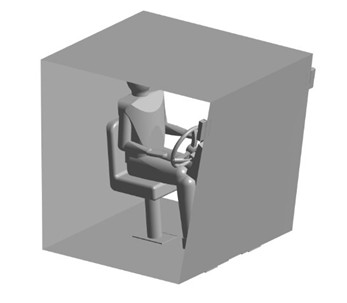

1. Geometry Cleanup & Domain Setup

- ● Cleaned and simplified truck cabin geometry

- ● Defined internal airflow domain, excluding non-essential parts to enhance simulation speed

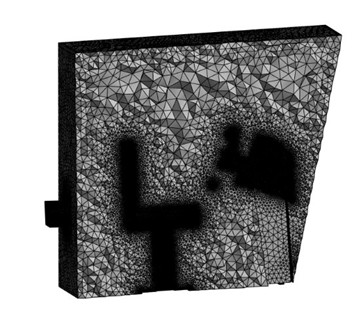

2. High-Quality Meshing

- ● Generated precise CFD mesh

- ● Applied boundary layer inflation to capture near-wall airflow and heat transfer effects

3. Boundary Conditions Setup

- ● Assigned inlet velocity conditions

- ● Specified thermal loads, outlet pressure, and wall properties to reflect real-world use

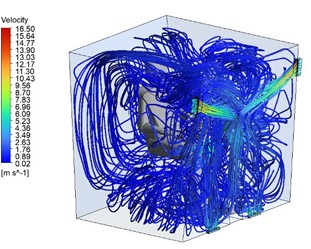

4. Steady-State Flow Simulation

- ● Used turbulence models like k-ε or SST for accurate airflow modeling

- ● Integrated additional louvers and refined geometry to improve airflow routing

5. Result Analysis

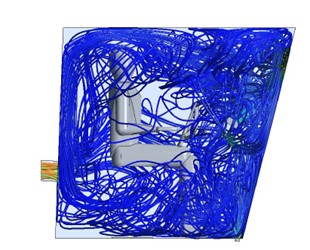

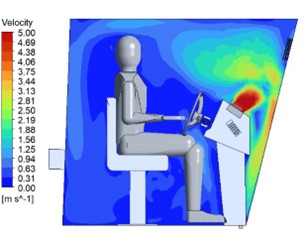

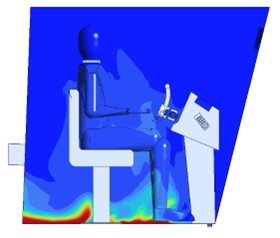

- ● Visualized streamlines to understand airflow paths

- ● Evaluated velocity distribution at louvers

- temperature contours in driver and windshield zones

- ● Assessed defrost/defog efficiency on glass surfaces

Performance Highlights

- ✔ Achieved required Velocity at all louver exits

- ✔ Uniform temperature and airflow in the driver zone

- ✔ Significantly improved windshield defogging and de-icing

- ✔ Suggested new louver positions for optimal comfort and performance

If you would like to know more about this topic.