Metal extrusion simulation enables Engineers to produce complex profiles with tight tolerances, quality surface finishes, and high strength properties. It will help in achieving productivity gains by reducing product development costs and improve extrusion quality, increasing production yield and customer satisfaction.

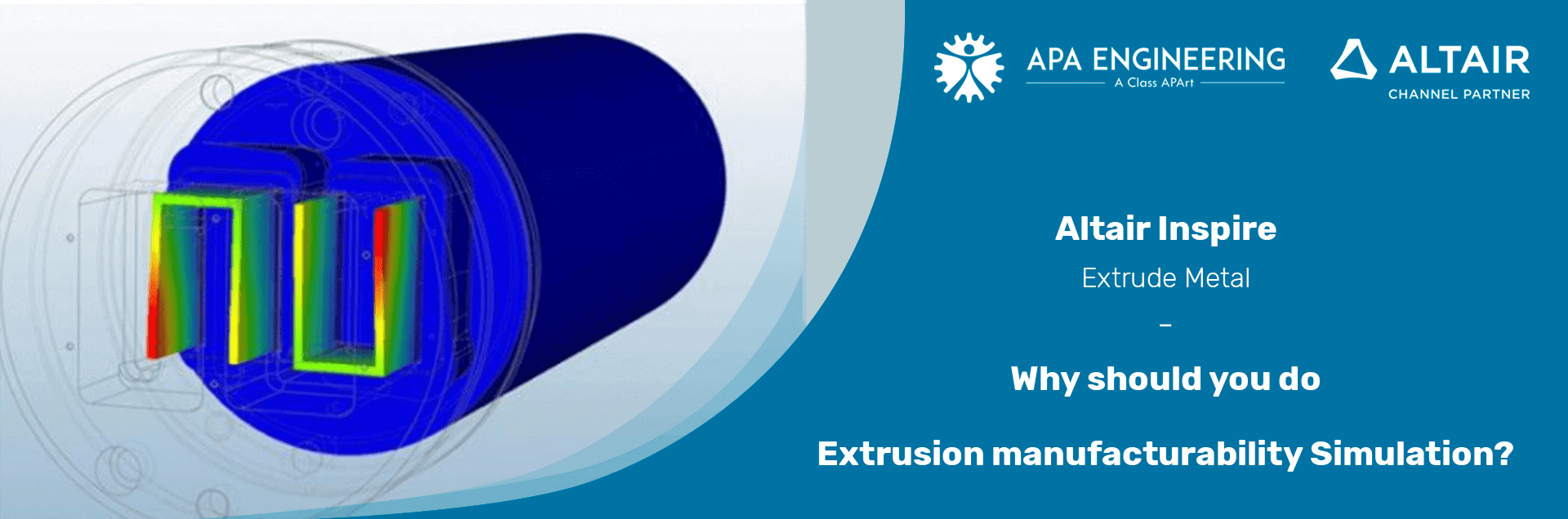

What is Altair Extrude Metal?

This tool is meant for use in the early design phase to simulate the metal extrusion process.

| Capabilities: | Benefits of Altair Inspire Extrude: |

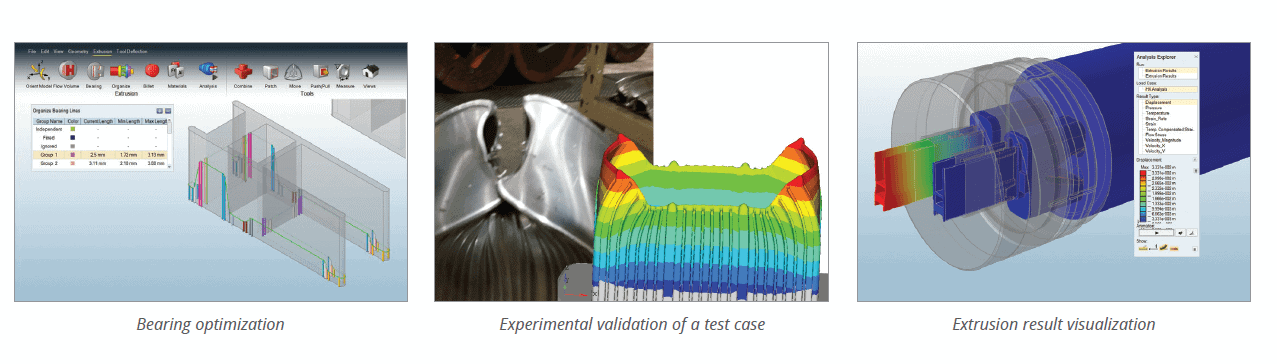

| ● Support for all Die types | ● Validate and Correct Die Design |

| ● Virtual Die trials | ● Extrude New Alloys |

| ● Tool Deflection Analysis | ● Determine Die Stresses and Failure |

| ● Contact friction | ● Increase Productivity, Increase Recovery and Reduce Scrap |

| ● Optimize Die Model | ● Determine Product Quality |

| ● Extrusion System management | ● Quenching Analysis |

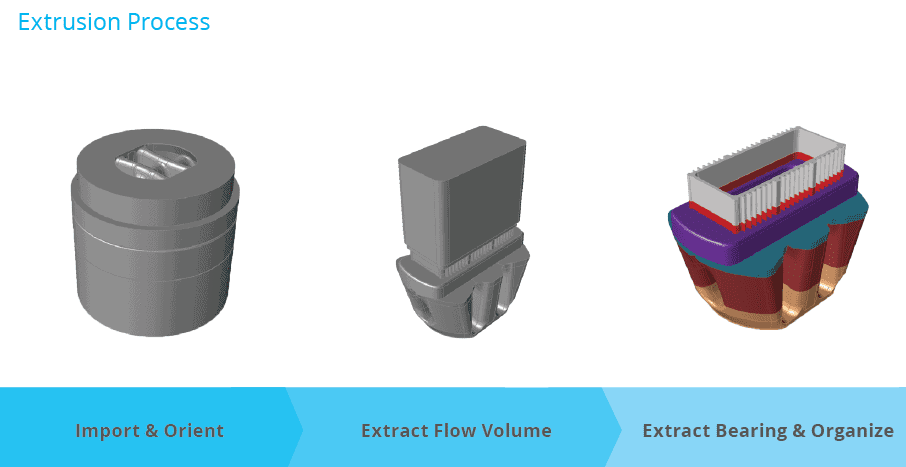

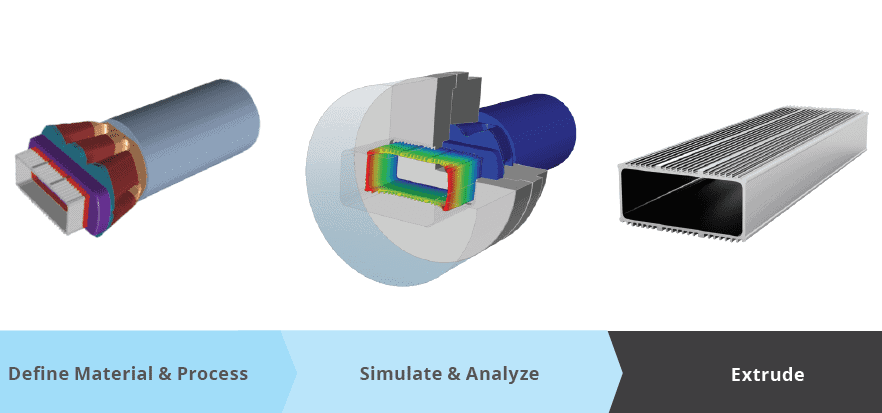

Workflow :

Customer Story: APEL Extrusions

Challenge: To reduce the cost involved in the current the inefficient trial & error process adopted in the development the Extrusion product.

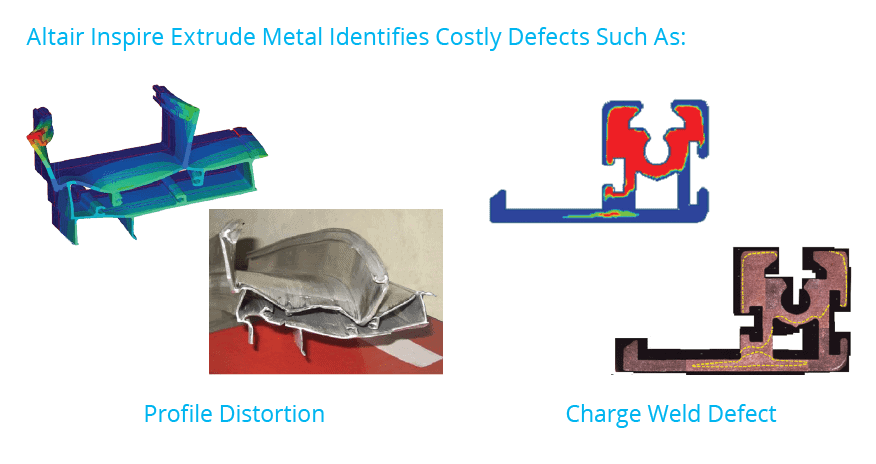

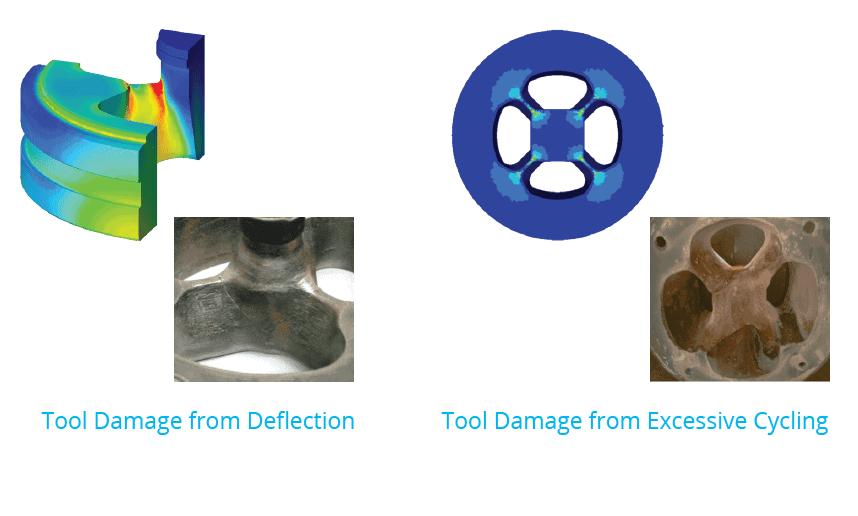

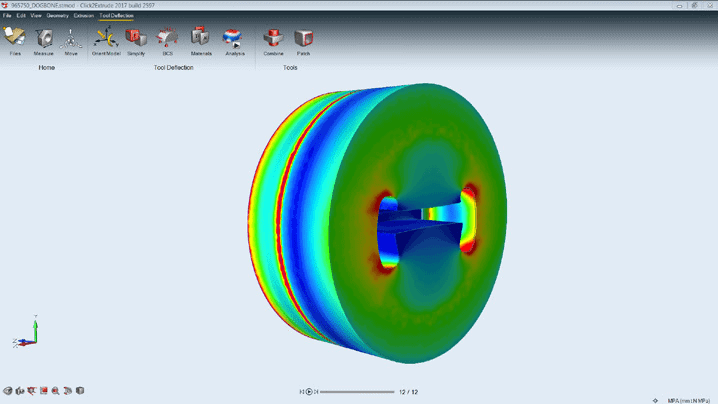

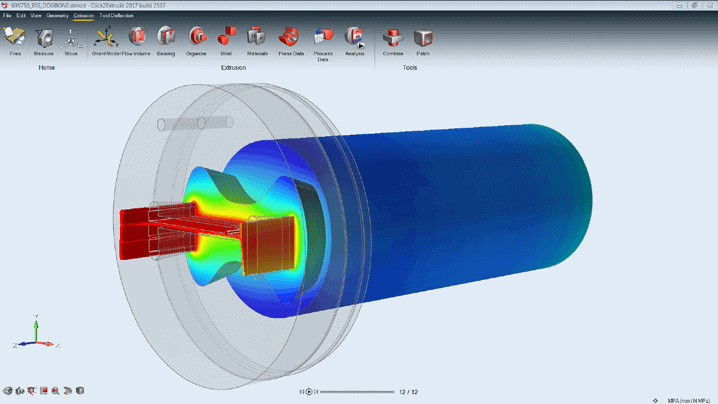

Inspire Extrude can detect the visible or invisible defects (like profile distortion, Skin defects, Die deflection & others.) during the simulation. Based on the simulations, they were able to determine the feasibility of the current design process & modify.

Tool Deformation Analysis Showing Critical Regions

Flow Simulation Showing Temperature Contour and Nose Cone

The author, Angayar Kanni T Business Development Engineer drive global strategy for engineering solutions at APA Engineering.

she can be reached at kanni.t@apaengineering.com, Contact Number: +91-9047781140

Banner Picture Courtesy – Altair

Content Courtesy – Altair Engineering

If you would like to know more about this topic.