Supplier management is a structured program for overseeing vendor interactions to maximize their business impact. With over 24 years of expertise, APA delivers comprehensive supplier management services globally, relying on a database of 600+ suppliers to provide reliable, efficient supply chain solutions.

Key Aspects of

Supplier Management

Standards

Capabilities of APA in

Supplier Management Solutions

Your Trusted Partner for Seamless Supplier Incorporation

Buyer-centric Relationship

- Unequivocally buyer-centric, representing overseas companies sourcing products from India.

- Maintains transparency in all supplier interactions, both commercially and technically.

- Acts as the overseas buyer’s extended sourcing arm, consistently prioritizing buyer interests .

Holistic Quality Assurance

- Inspectors in key locations support all manufacturing stages, from supplier validation to pre-dispatch inspections.

- Provides Corrective and Preventive Actions (CAPA) for customer complaints.

- Online dashboard offers easy, secure access to inspection reports and quality data.

Certified and Confidential Suppliers

- Partnership with OEM and ISO-certified suppliers.

- Comprehensive screening processes for supplier compliance.

- Supplier validations conducted by skilled inspectors.

Cost Optimization

- Domain experts collaborate with local managers to identify cost-saving strategies.

- Continuous evaluation of market trends informs optimization efforts.

- Delivers high-value, cost-effective solutions to clients.

Focus in

Supplier Management

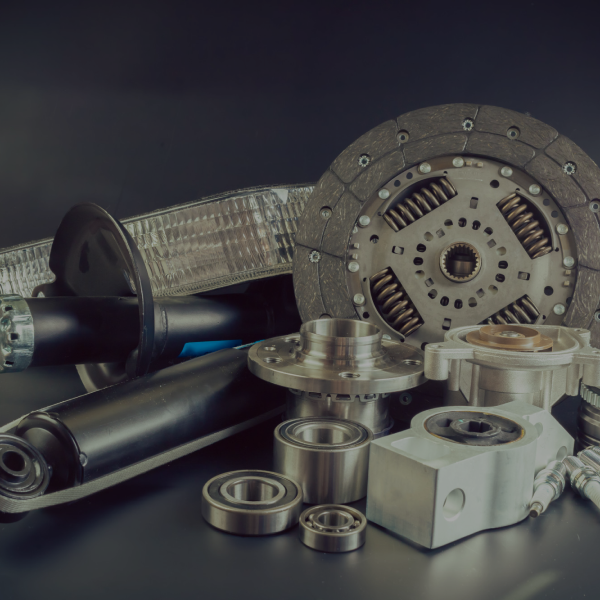

Specialized Solutions for Automotive and Discrete Engineering Products

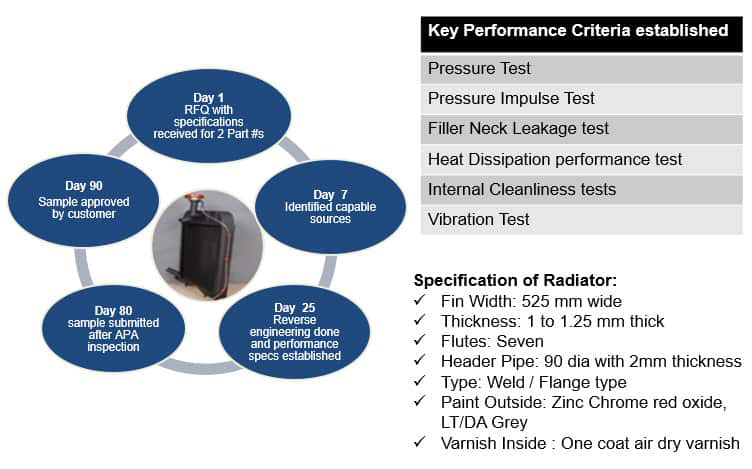

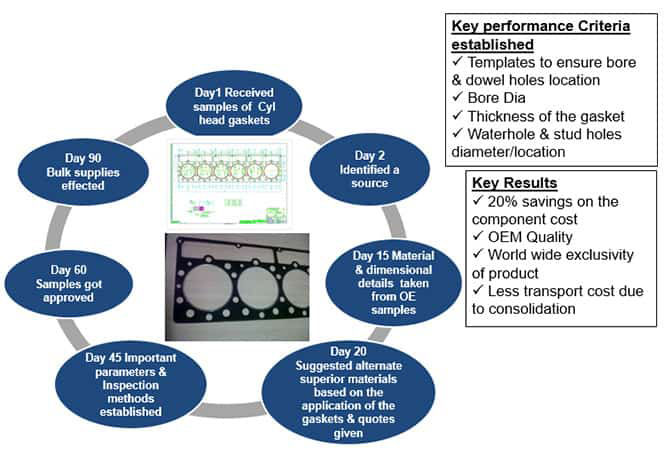

APA’s expertise extends to sourcing Automotive and Discrete components, including cylinder liners, pistons, rings, connecting rods, bearings, water and oil pumps, radiators, camshafts, and crankshafts, with specifications tailored to customer needs.

Each product undergoes rigorous quality checks at every production stage, from raw material procurement to final components. Processes include:

Casting

Forging

Machining

Stamping

Fabrication

Sourcing materials include steel, cast iron, non-ferrous metals, and special alloys based on client requirements.

APA's 7 Phases in New Product Development

Driving Quality from Concept to Market

At APA, we pride ourselves on our ability to drive quality throughout every stage of product development. Leveraging our deep expertise and understanding of products and vendor capabilities, we add significant value during New Product Development (NPD).

New Product Development

Creating and bringing a new product to market

Supplier Audits

Assessing and evaluating the performance of suppliers

Confidentiality & Exclusivity

Protecting the privacy and exclusivity of newly developed products to safeguard intellectual property

Tooling Development

Creating and refining the tools and equipment for production

PPAP samples and documentation

Providing samples and documentation to ensure that production processes meet customer requirements

Production Processes

Overseeing the procedures used to manufacture products

Pre-dispatch Inspections

Conducting thorough inspections to verify product quality before they get dispatched.

Why Choose APA for

Supplier Management Solutions

SUPPLIER LIAISON

Automated Reminders

Sending auto reminders to suppliers to

keep them on schedule

Performance Analysis

Evaluating delivery performance with

actionable insights for improvement

Regular Communication

Weekly calls and regular visits to maintain strong

supplier relationships

Project Tracking

Utilizing Gantt charts for tooling, parts

development, and bulk production timelines

Collaborative Support

Sharing expertise and domain knowledge

with suppliers as needed

Open Orders Review

Continuous monitoring and review of open orders to

ensure timely progress

Customer Engagement

Regular Updates

Weekly scheduled calls to provide firsthand information on developments and production

Supplier Transparency

Offering transparent and open

information about suppliers

Interactive visits

Inviting customers to visit

and meet with suppliers

Order Reconciliation

Ensuring continuous review and

reconciliation of open orders

Portfolio of Sourced Products

Parts

Process-Related

Materials

Parts

- Cylinder Liner

- Pistons & Rings

- Con rods

- Bearings & Bushings

- Water & Oil Pumps

- Radiators & Oil Coolers

- Camshafts & Crankshafts

- Valves, Guides & Seats

- Fuel Injection part

- Alternators & Starters

- Generators & Drives

- Armatures, Field Coils

- Switches

- Regulators

- Cable assembliea

Process-Related

Casting

- Sand

- Shell

- Investment

- Gravity

- Diecastings

Forging

- Hot

- Cold

- Orbital

- Forming

Machining

- CNC

- VMC,HMC

- Turning centers

- Screw Machining

- Conventional

Materials

Steel

- Plain carbon Steel

- Low Alloy Steel

- Hig Alloy steel

Cast Iron

- Gray

- Malleable

- Ductile

Non Ferrous

- Aluminium and alloys

- Copper and its alloys

- Zinc alloys Zamak

Case Studies

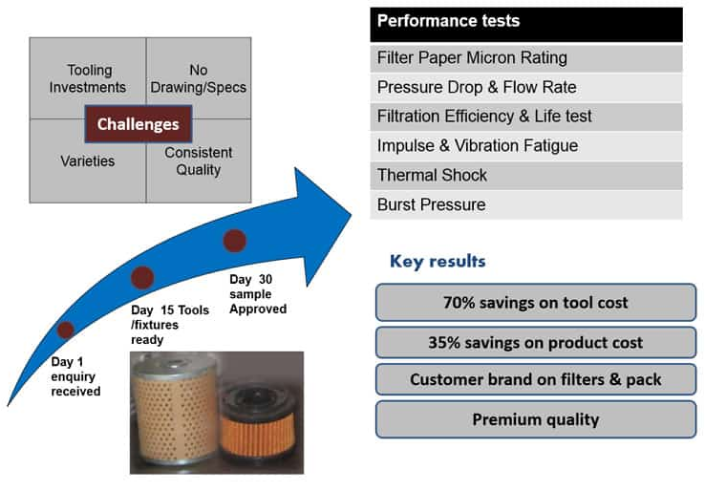

Input: thorough market research on best of Hydraulic Pumps manufacturers, APA has zeroed in on one of the top manufacturers in India, and the OE sample has been offered to them for basic study and costing for the Pump.

Deliverables: Apart from locating the manufacturer of the Pump, APA has assisted this manufacturer in finding out the sources for child parts like Pistons, Valve Body assembly, Adapters, O Rings, etc.

Key Challenge: Before Pump lot was confirmed at the manufacturer end, we had done 40 hrs of test run and 20 samples was provided till we reached approval for sample.

Benefits: APA quality inspectors inspects checks performance of pump and only picks as per requirement by customers. The material is then sent to APA warehouse for consolidation, all inspection reports are available in our “Online Inspection Dashboard” for customer to view it. Since the Pumps are dispatched to end customers directly savings in transportation Costs, and supply lead times as well

Remote Working: Client set up separate logins for APA staff to remote login into their server. Thanks to the 12 hour time difference , daily work could be QC checked by the client during his working hours.