Understanding IMDS Compliance

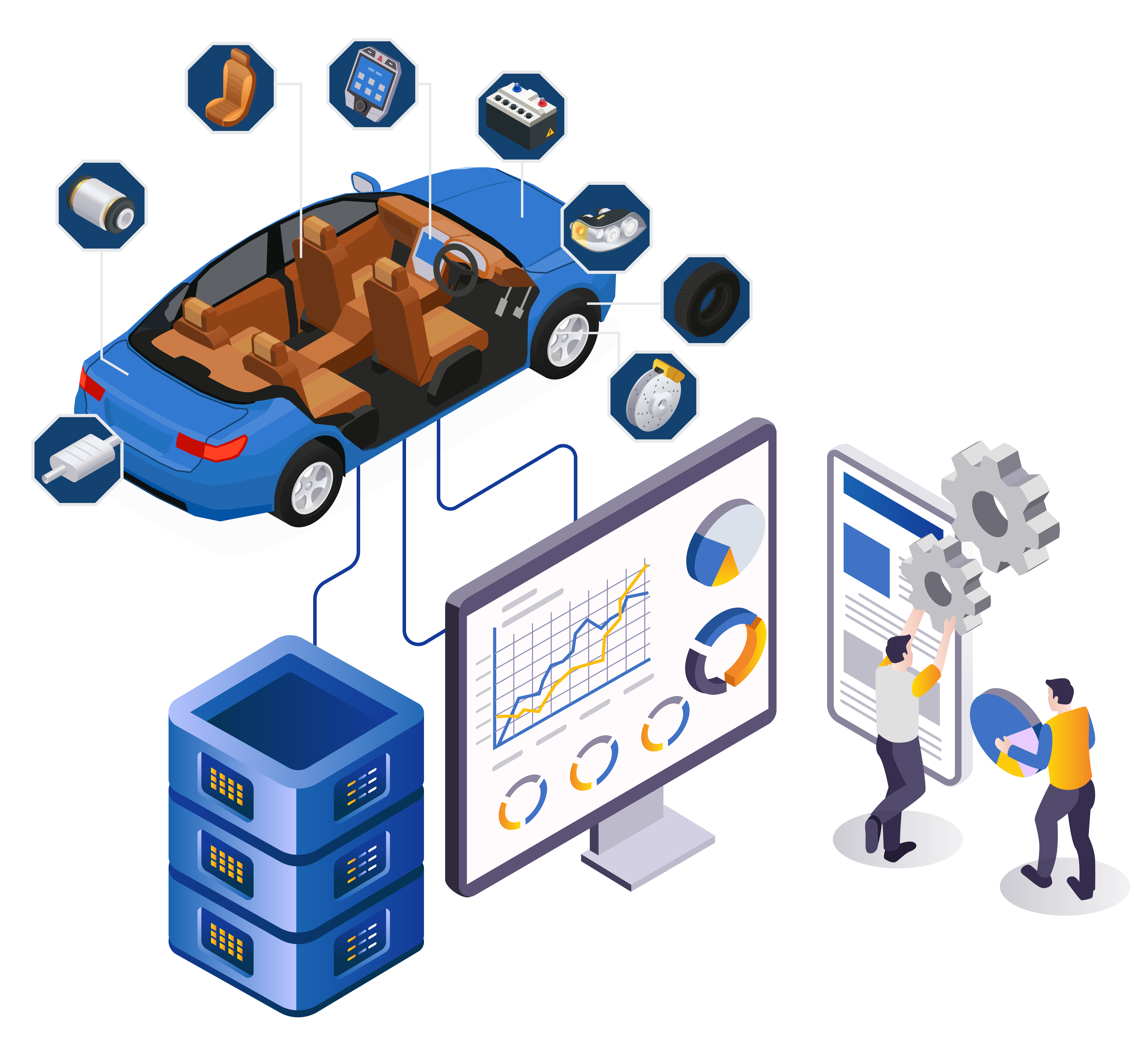

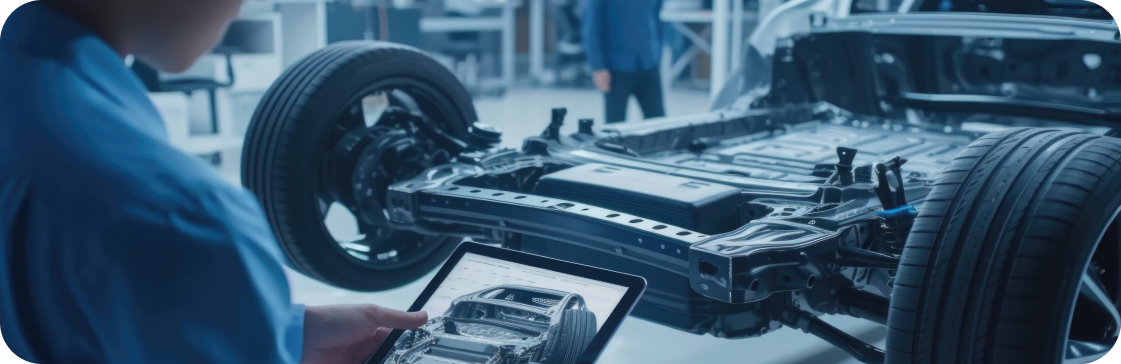

The International Material Data System (IMDS) is a centralized database used in the automotive industry. It contains detailed information about the materials and substances used in vehicle components. Manufacturers and suppliers contribute to the database by providing material types, chemical compositions, and recycling information. This data is then utilized to evaluate vehicles' environmental impact throughout their lifecycle, from the manufacturing stage to the end-of-life disposal and recycling phase. IMDS is often associated with End-of-life Vehicle (ELV) Compliance.

Objective

-

Standardization of Material Data Reporting: IMDS database aims to standardize material data reporting across the automotive industry supply chain, helping ensure consistency and compatibility in exchanging material information.

Standardization of Material Data Reporting: IMDS database aims to standardize material data reporting across the automotive industry supply chain, helping ensure consistency and compatibility in exchanging material information. -

Material Substitution: IMDS helps manufacturers assess alternative materials and substances for vehicle production. It achieves this by using extensive material data to support decision-making processes for better performance, cost reduction, and compliance with evolving regulatory requirements.

Material Substitution: IMDS helps manufacturers assess alternative materials and substances for vehicle production. It achieves this by using extensive material data to support decision-making processes for better performance, cost reduction, and compliance with evolving regulatory requirements. -

Compliance with Regulations: IMDS assists automotive manufacturers and suppliers in complying with various regulations and directives related to materials and substances used in vehicles. This includes regulations such as the European End-of-Life Vehicle Directive (ELV), Restriction of Hazardous Substances Directive (RoHS), (RRR) Reduce Reuse Recycle directives, and GADSL Global Automotive Declarable Substance List

Compliance with Regulations: IMDS assists automotive manufacturers and suppliers in complying with various regulations and directives related to materials and substances used in vehicles. This includes regulations such as the European End-of-Life Vehicle Directive (ELV), Restriction of Hazardous Substances Directive (RoHS), (RRR) Reduce Reuse Recycle directives, and GADSL Global Automotive Declarable Substance List -

Supply Chain Transparency: IMDS enables transparent tracking of automotive supply chain substances, ensuring product safety and regulatory compliance.

Supply Chain Transparency: IMDS enables transparent tracking of automotive supply chain substances, ensuring product safety and regulatory compliance. -

Environmental Responsibility: IMDS (International Material Data System) provides comprehensive information on vehicle materials, promoting environmental responsibility and sustainability in the automotive industry. It helps identify and reduce hazardous substances while facilitating material recycling and recovery. Using IMDS, the automotive industry can minimize its environmental impact and ensure a safer future for everyone

Environmental Responsibility: IMDS (International Material Data System) provides comprehensive information on vehicle materials, promoting environmental responsibility and sustainability in the automotive industry. It helps identify and reduce hazardous substances while facilitating material recycling and recovery. Using IMDS, the automotive industry can minimize its environmental impact and ensure a safer future for everyone

6 Key Challenges of IMDS Implementation

8 Effective Service By APA To Help you Comply With IDMS

Material Research and IMDS Data management

Accurate and comprehensive regulatory reporting is ensured through thorough research to identify materials and seamless data entry into IMDS. Ongoing maintenance and continuous monitoring of IMDS data for hazardous substances to mitigate risks of non-compliance.

Compiling, Change, and

Processing of MDS

Expert compilation, swift change management, and precise processing of Material Data Sheets (MDS) to streamline reporting and ensure regulatory adherence.

IMDS Software

Support

MDS Xpress provides dedicated software support for IMDS, which ensures efficient data management, prompt troubleshooting of technical issues, and smooth operations.

Supplier

Coordination

Continuous engagement with suppliers, including follow-up, data collection, and MDS validation, fostering collaboration and compliance across the supply chain.

RRR and Regulatory

Compliance Support

We offer robust support for RRR and RoHS compliance, offering consultation and guidance to effectively navigate regulatory complexities

Breaking Language

Barriers

Effective communication with suppliers and clients in English, German, Chinese, Korean, and Thai, ensuring seamless collaboration and a clear understanding of requirements.

IMDS

Training

Our IMDS training programs are customized to provide personnel with the skills and knowledge needed for material data reporting and compliance management.

Expert Guidance and

Support

From initial consultation to ongoing assistance, our IMDS experts are committed to providing exceptional service and support to our clients, helping them navigate the complexities of IMDS compliance with confidence and ease.

CAMDS

Your gateway to material data management tailored to the Chinese automotive landscape.CAMDS (China Automotive Material Data System) is a system like IMDS, but it is specifically designed for the Chinese automotive industry. The CAMDS platform collects, manages, and shares material data related to automotive manufacturing. Our customized solutions make it easy for you to navigate the intricacies of CAMDS, promoting transparency, efficiency, and success in the dynamic Chinese automotive market.