The US automotive industry is often credited as, literally, the engine of the economy. This industry alone contributes to more than 3% of the GDP and is one of the largest jobs provider in America.

However, with the onslaught of Corona, the auto industry is under severe duress and the impact is more significant on small and medium components and accessories manufacturers who supply to the automotive majors and the aftermarket.

US businesses have always been enterprising, entrepreneurial, and adopting newer ways to survive and grow. In this article, we give you 3 real case studies where such manufacturers adopted best practices of global engineering to set themselves on the road to improved productivity and profits.

Case Study 1: Manufacturer of Steering Knuckle

This Michigan based manufacturer saw more than 35% improvement in cost savings by collaborating with CAE experts across the globe to deliver high-performance, light-weight steering knuckles that meet stringent guidelines of OE.

Read more here

Case Study 2: Manufacturer of Universal Drive Shafts

With mounting sales pressure, this manufacturer of UDS from Nebraska devised a new strategy to accelerate customer interest in their products. They amped up the quality of their catalogs with high-definition 3D rendered images and novel cataloging aid tools by collaborating with niche specialists skilled in engineering & cataloging, on the other side of the world.

Read more here

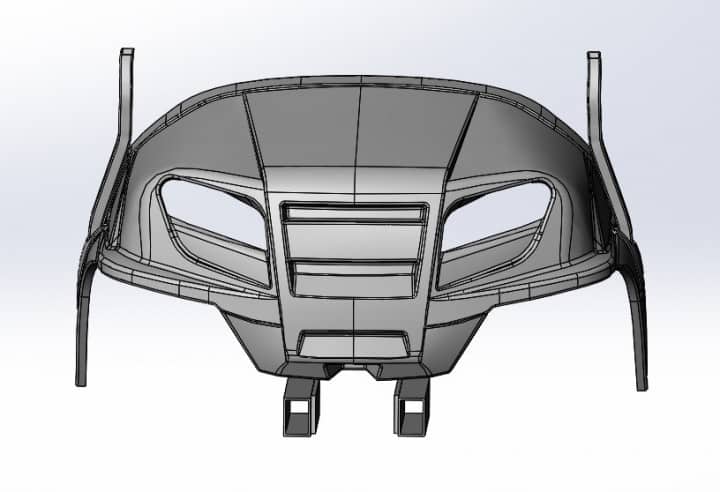

Case Study 3: Distributor of Parts for Off-Road Applications

When life throws lemons at you, make lemonades. This parts distributor utilized the lean period to completely re-engineer parts and accessories for off-road sports vehicles for improved quality at substantially lower costs.

Read more here

If you would like to know more about this topic.