Client:

Our client is a major supplier of critical suspension components such as Steering knuckles, Brake drums, Brake discs, Hubs, Brake calipers, Carriers, Differential case to passenger car manufacturers like GM, Ford, Volvo, Honda & BMW.

Scope:

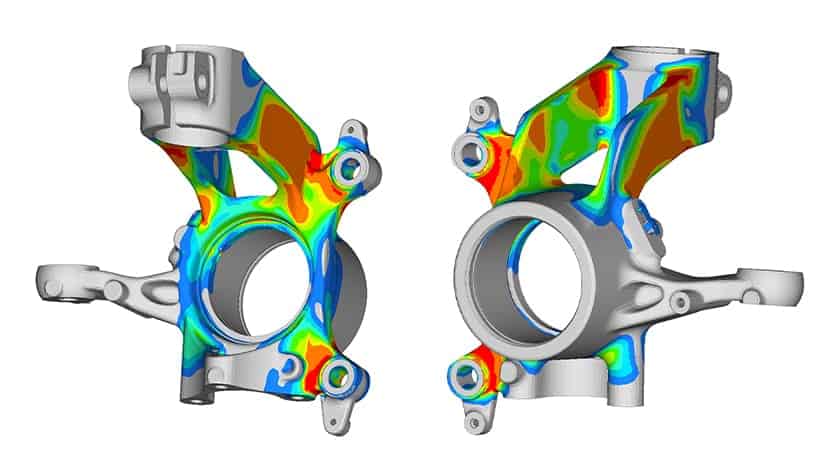

For new Automotive Program, develop an Optimized steering knuckle design meeting the stringent weight target given by OEM and making sure the design meets all the performance targets for:

- Stiffness at attachment locations

- Fatigue life cycle counts for various Service loads

- Permanent set under Extreme Nonlinear static load

- Permanent set under Nonlinear Dynamic loads

- Plastic strain levels under Impact loads

Why APA?

APA Engineering is the CAE technology partner, leading the CAE driven development with 8+ years of experience in CAE drive design development of Steering knuckles and other suspension components, Validating, optimizing ( light-weighting) components, participating and participate in Design review meetings with OEMs, giving a competitive edge to our customers enabling them to win global programs.

Challenges involved:

- Developing a high fidelity model, capturing Bolt Pretension and Shrink fit effects accurately to account for Pre-stress, before applying service/Extreme loads.

- Arriving at a converged solution with nonlinearities such as Material, Geometric and contacts under highly nonlinear loads.

Standards: OEM’s internal standards & Test specifications

Software used:

- Altair’s Hyperworks for Pre & Post Processing

- Dassault System's Abaqus for Solving

Value Delivered:

- Participate in Design review meeting as CAE expert representing our client and proving the lightweight design.

- Entire development cost is just 35 % of the cost of typical consultant charges in USA.

If you would like to know more about this topic.