Client

A global engineering organization providing specialized equipment and solutions for energy and industrial applications.

Why APA Engineering

APA’s CFD team has strong expertise in simulating complex internal flows using ANSYS CFD for steady-state and turbulent conditions. Our experience in pressure drop, velocity distribution, and flow behavior studies for valves and fluid handling equipment enabled us to deliver accurate, design-focused insights.

Scope

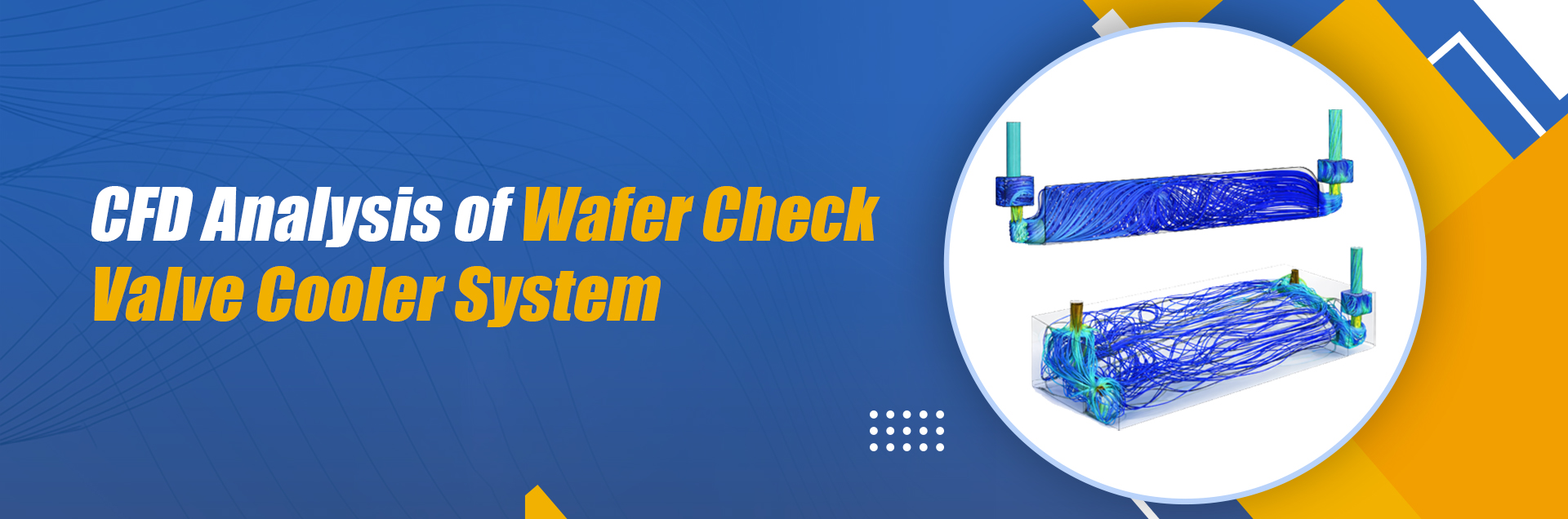

Perform Computational Fluid Dynamics (CFD) analysis of a wafer check valve cooler system to:

- ● Study pressure and velocity distribution inside the cooler and valve, and

- ● Evaluate overall pressure drops for different operating flow conditions and configurations, including single and multi-cooler arrangements.

Our Approach

- ● Cleaned and prepared the CAD geometry of the wafer check valve cooler assembly.

- ● Generated high-quality CFD meshes with boundary layer refinement.

- ● Defined fluid properties for a water–ethylene glycol mixture and applied operating boundary conditions.

- ● Implemented the SST k–Omega turbulence model for accurate turbulent flow prediction.

- ● Simulated multiple design scenarios with and without valves, and for single and three-cooler configurations.

- ● Post-processed flow patterns, velocity contours, and pressure fields to assess system behavior.

Value Delivered

- ● Provided clear visibility into internal flow behavior and pressure characteristics of the valve–cooler system.

- ● Comparison of multiple design configurations and Optimization early in the design cycle much before the first physical prototype build accelerating the product development process.

- ● Delivered a comprehensive CFD report to aid engineering decisions and stakeholder reviews.

Result

APA Engineering acted as an extended CFD design partner, helping validate and optimize the wafer check valve cooler design through high-fidelity simulation and domain expertise.

👉 Get a CFD Analysis for Your System