Client Overview

Our client is a North American solutions provider specializing in remanufactured electronics, rotating electrical systems, mechatronics, and propulsion battery solutions.

Project Scope

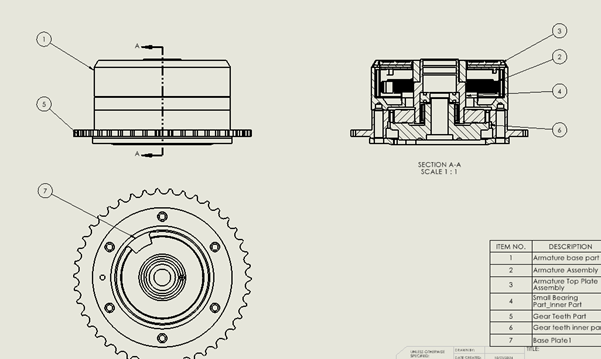

The reverse engineering of the actuator assembly for an Automobile EV vehicle involved the following activities.

● Measurement and scanning of all individual parts and assemblies using CMM and 3D scanning technologies.

● Creation of fully parametric 3D CAD models and detailed 2D engineering drawings.

● Development of complete electrical schematics.

● Identification and analysis of internal components through controlled dismantling of the actuator.

Why APA?

APA has a dedicated reverse engineering team supported by an exclusive in-house laboratory equipped for probing, non-contact 3D scanning, and precision dimensional measurement of automotive and non-automotive components. In addition, APA possesses the capability to identify and validate the chemical and mechanical properties of materials, ensuring accurate and reliable design reconstruction.

Actuator Reverse Engineering Process

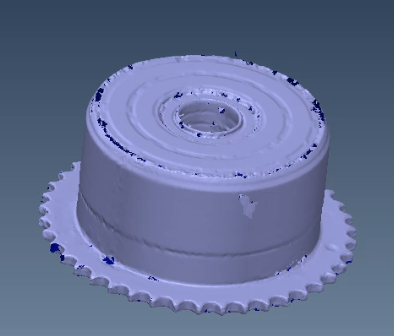

SCANNING

- ● Preparation of components for scanning.

- ● Secure and accurate fixturing of parts to ensure scan stability.

- ● Capture of symmetry and profile measurements prior to full scanning.

PREPROCESSING

- ● Removal of noise and unwanted data from scan results.

- ● Alignment of scan data to the defined coordinate system.

- ● Export of processed scan data in STL format.

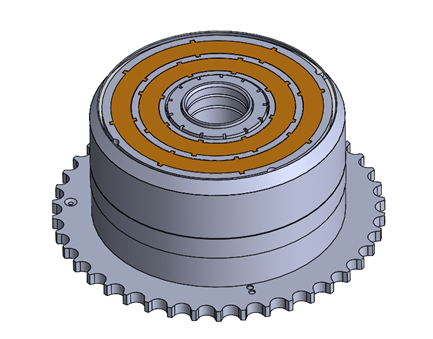

PARAMETRIC MODELING

- ● Import of STL data into CAD software.

- ● Extraction of curvature profiles and generation of outer surfaces in accordance with customer standards.

- ● Development of fully parametric CAD models based on scanned data.

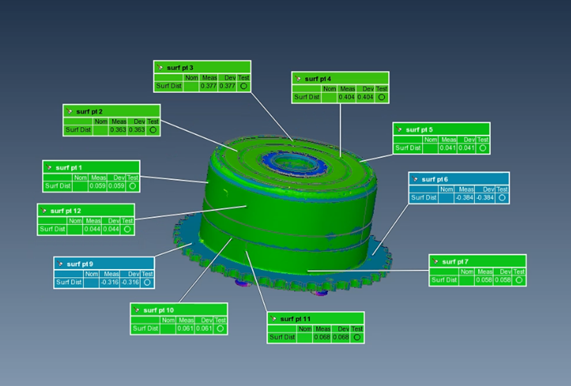

QUALITY CHECK

- ● Overlay comparison between scanned data and the developed 3D CAD model.

- ● Identification and analysis of dimensional deviations.

- ● Generation of detailed inspection and comparison reports.

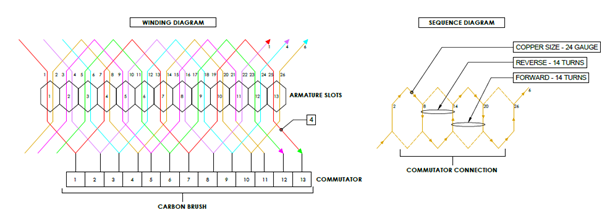

ELECTRICAL SCHEMATICS

- ● Measurement of armature and coil resistance.

- ● Creation of electrical schematics, including armature and winding details.

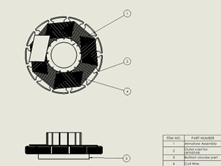

2D DRAWING

- ● Generation of 2D drawings from 3D models.

- ● Preparation of complete Bills of Material (BOM).

Value Delivered

APA delivered a comprehensive one-stop solution by extracting both mechanical and electrical design information for the actuator. This integrated approach significantly reduced overall project cost and turnaround time compared to onshore execution, while maintaining high accuracy and quality standards.

Need accurate reverse engineering for automotive or EV components?