Client:

Our customer is an Independent/integrated work cells and automation equipment manufacturer in North America.

Scope:

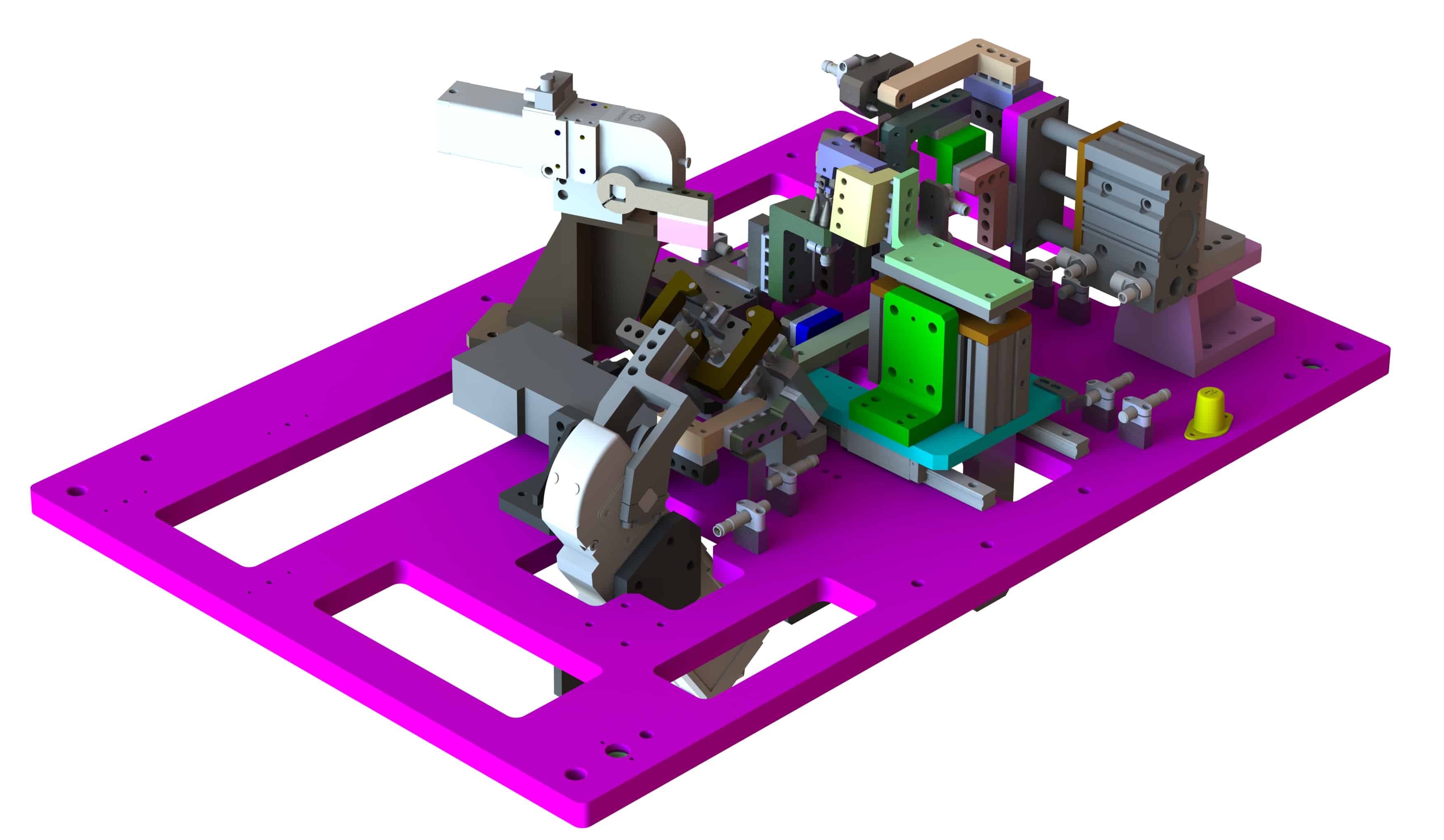

The scope is to design welding fixtures to weld all the components of “Brake pedal assembly”. This project had a very stringent timeline. Since their design engineers are engaged with other projects, the client was looking for an external design team to execute this project.

Why APA?

APA has around 8 years of experience in the design of automation equipment, welding fixtures, assembly line automation, work stations/work cells, and EOAT (End Of Arm Tools).

Design Challenges involved:

All the 6 components of Brake pedal assembly have to be welded by using only 2 welding fixtures so that it can be fitted into the existing machine setup.

Design process:

- Deciding the number of sub-loads required to weld all the components.

- Arresting all the degrees of freedom of the components by using locating pins, power clamps, pneumatic linear actuators, and nests.

- Designing different hole positions and hole sizes for assembly process Poka-Yoke.

- Incorporating the sensors to check the presence of the components.

- Performing Sizing calculations to select Linear actuator, swing clamps, and power clamps.

- Optimizing all the sub-loads within the provided 2 fixture base plates.

- Ensuring the reach of welding gun for all the weld bead locations by providing enough space for welding gun.

- Incorporating spatter resistance cylinders and also the “Amco18” sheet as spatter proof cover for all the important GD&T surfaces.

- Ensuring there is no clash when the weld gun moves.

- Preparing assembly drawings and Bill of Materials.

Value delivered:

- We have performed sizing calculations of long-lead items such as spatter resistance linear actuators, Clamps, etc., and get the confirmation from the respective manufacturers during the initial stage of design completion. This helped to speed up the construction schedule.

- APA Engineering is an “On-Demand Extended Design house” for our client. Design cost was just 40 % when compared to onshore.

If you would like to know more about this topic.