Client:

Our client is the most trusted partner in delivering intelligent automation solutions. They specialize in welding and joining, automated assembly, and test, industrial parts washers, and final assembly systems.

Scope:

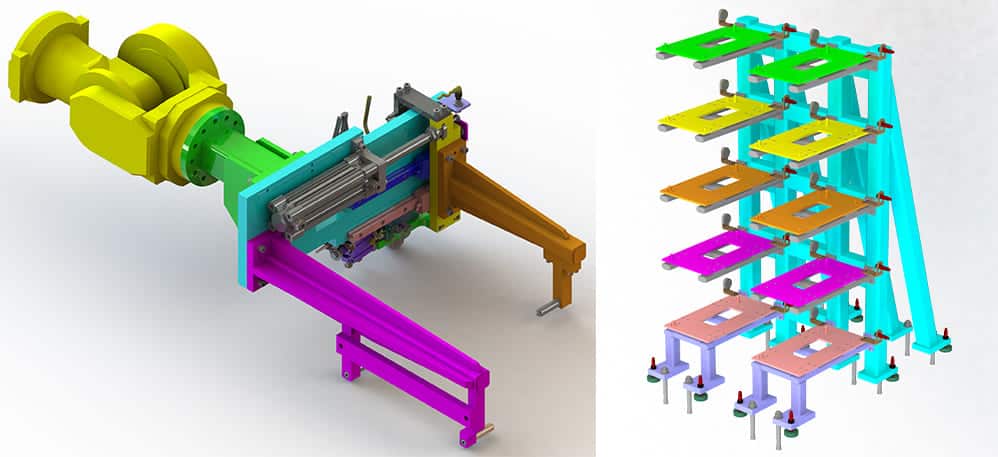

The scope is to design an End of arm tool (EOAT) to pick and place 4 different Engine Blocks from the CNC machine to the Part Stand. And also, to design a Part Stand to hold 10 numbers of engine blocks.

Why APA?

APA has around 8 years of experience in the design of automation equipment, welding fixtures, assembly line automation, work stations/work cells, and EOATs

Design Challenges involved:

- Designing a common EOAT to handle 4 different Engine blocks.

- Designing a part stand with a common fixture to hold 4 different Engine blocks. Optimizing the height of the part stand negating collision of EOAT to during pick and place motion of Engine blocks.

Design process :

- Designing the EOAT by incorporating pins and pneumatic clamps to hold 4 different components and choosing its material depending upon the application.

- Designing the part stand with 5 stacks to keep 2 engine blocks in each stack (totally 10 engine blocks), having a common fixture to accommodate 4 different engine blocks by incorporating the pins.

- Performing sizing calculations to select linear guides and linear actuators.

- Incorporating different hole positions and hole sizes for assembly process Poka-Yoke.

- Designing the EOAT structure to easily connect/disconnect with Robot’s quick changer.

- Ensuring there is no collision while the EOAT pick and place the Engine blocks in the part stand.

- Modifying the part stand structure design based on the FEA recommendations.

- Preparing assembly drawings and Bill of Materials.

Value delivered:

- Validating the designed part stand structure by FEA to ensure deflection & stress levels are well within the limits.

- We have performed sizing calculations of long-lead items such as Linear actuator, Linear guides, shot pin cylinder, etc., and get the confirmation from the respective manufacturers during the initial stage of design completion. This helped to speed up the construction schedule.

- APA Engineering is an “On-Demand Extended Design house” for our client. Design cost was just 40 % when compared to onshore.

If you would like to know more about this topic.