Client:

Our Client is a distributor and manufacturer of parts and accessories for the Recreational Vehicle (RV) industry of North America.

Scope:

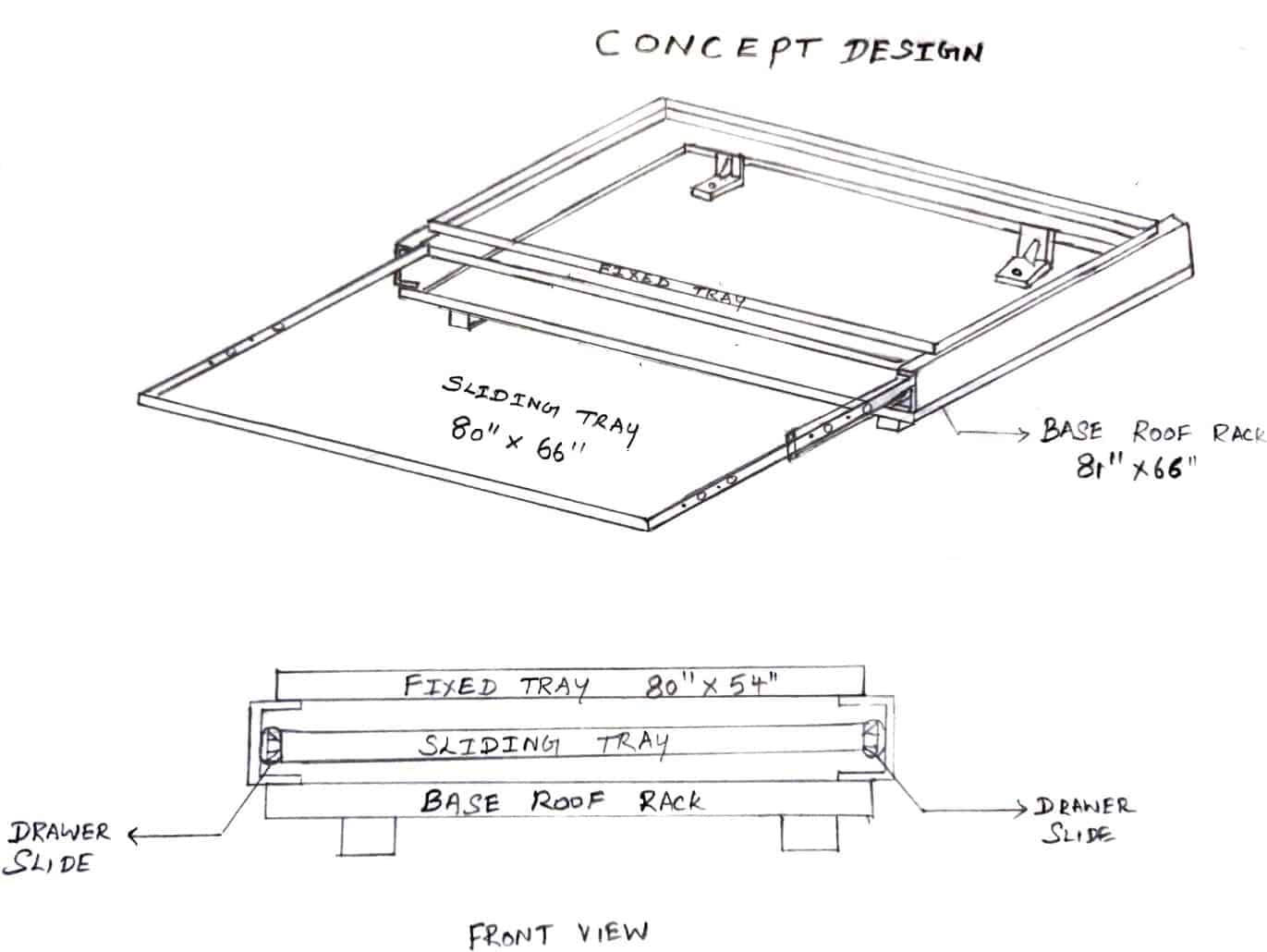

The scope is to design a lightweight, non-corrosive solar panel tray system with a sliding mechanism for a Recreational vehicle.

Why APA?

APA has a dedicated team to work on designing and Reverse Engineering of Recreational vehicle components with an exclusive lab set up for Probing, Scanning (3D Non-Contact), and measuring dimensions.

Design Challenge:

- The challenge was to design this sliding tray system by using the standard size components such as C channel, L Angle, hollow tubes, Telescopic slides, plates, etc., which are commonly available in America, India, and China.

Design Process:

- Understanding the requirement of the product and obtaining concept approval from the client.

- Using aluminum material for the structure as it is a lightweight and non-corrosive material.

- Sizing the components including Telescopic slides which are commonly available in America, India, and China.

- Creating this sliding tray system as a flexible design to accommodate the installation of one more sliding tray in the opposite direction on top of the existing tray by rotating it to 180deg.

- Preparing part drawings, assembly drawings, and Bill of Materials.

Values Delivered:

- We have identified the manufacturers of standard components and the telescopic slides in all the 3 countries (America, India, and China) to speed up the time to market.

- APA Engineering is an “On-Demand Extended Design house” for our client. Design cost was just 40 % when compared to onshore.

If you would like to know more about this topic.