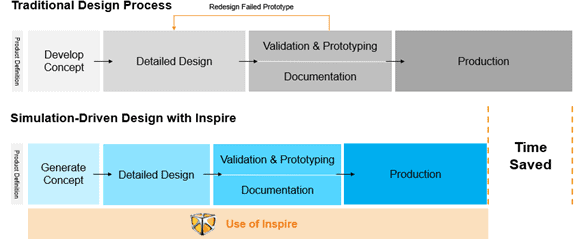

Industries are always looking for ways to reduce the manufacturing cost & to arrive at the optimum design for a product in the shortest possible time. This need has been amplified in the current scenario. Reducing weight, exploring different material options & manufacturing feasibilities will help in bringing down the manufacturing cost significantly. While striving for this, Strength and component life shouldn’t be compromised. Hence optimization of the design becomes essential.

What is Altair Inspire?

Inspire is a simulation software that accelerates the creation, optimization, and study of innovative, structurally efficient parts and assemblies through collaboration. It is easy to learn & gives results in seconds to minutes.

What Altair Inspire Can Do?

Applied at the very beginning of clean-sheet design programs and for design exploration of current production parts, Inspire allows designers and engineers to:

Benefits

Generate and simulate structurally efficient concepts quickly and easily

Customer Stories

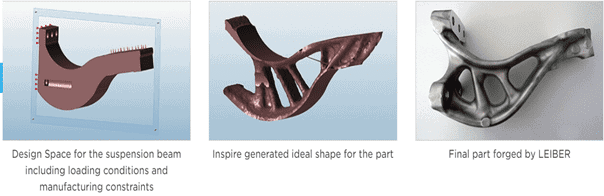

1. Leiber Group

A recent project at LEIBER required its engineers to redesign a component for a commercial vehicle. The previous part, a suspension beam, was made of cast iron. In this case, the customer required a lighter, yet equally strong new component. To design this part, LEIBER engineers used Inspire and a new material, AluXtrem, a high tensile forgeable alloy, also developed by LEIBER. In combination, Inspire and the new material received significant lightweight results. The resulting new component was more than 50 percent lighter than the previously used cast iron component, and a lead-time reduction in manufacturing and testing enabled a more economical production process.

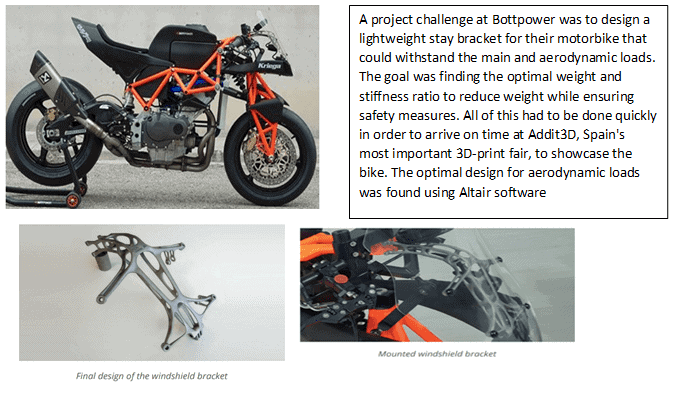

2. BOTT Power

3. Israeli Aerospace Industries

The goal of the project was to design a 3D printed support bracket for the thruster configuration required for the SpaceIL program. Since there was no previous machined bracket for this program, the targets were defined in accordance with the program’s mass budget and the spacecraft’s static & dynamic requirements. All of the topological optimization and design was done at designer level using Inspire and only the final validation required efforts of the stress analysis department.

For more details:Click Here

The author, Angayar Kanni T Business Development Engineer drive global strategy for engineering solutions at APA Engineering.

she can be reached at kanni.t@apaengineering.com, Contact Number: +91-9047781140

Banner Picture Courtesy – Altair

Article Reference – Altair

If you would like to know more about this topic.