Our Client:

Our Client is an intercontinental provider of climate control products for the Heating,Ventilation, air conditioning (HVAC) and refrigeration markets.

Scope:

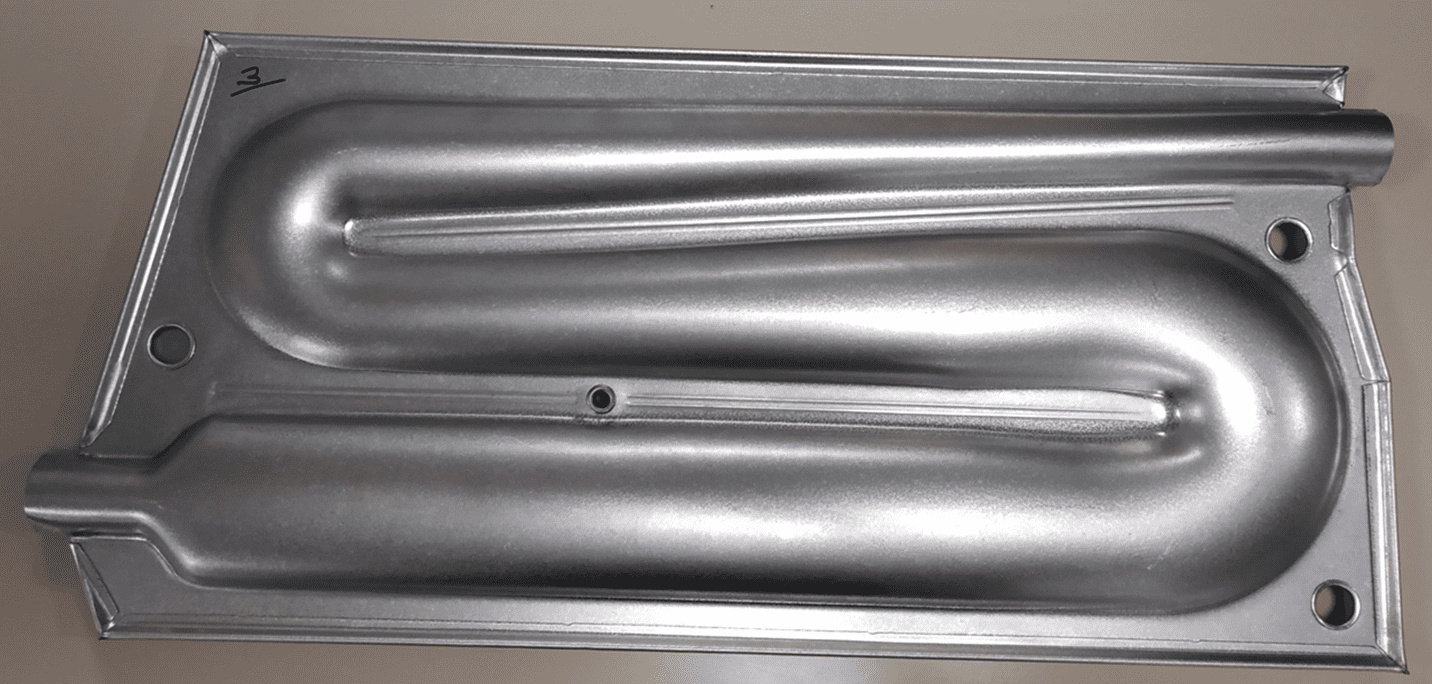

Reverse Engineering of Heat Exchanger Assembly.

- Measuring & Scanning of all parts/assemblies using CMM/3D Scanner

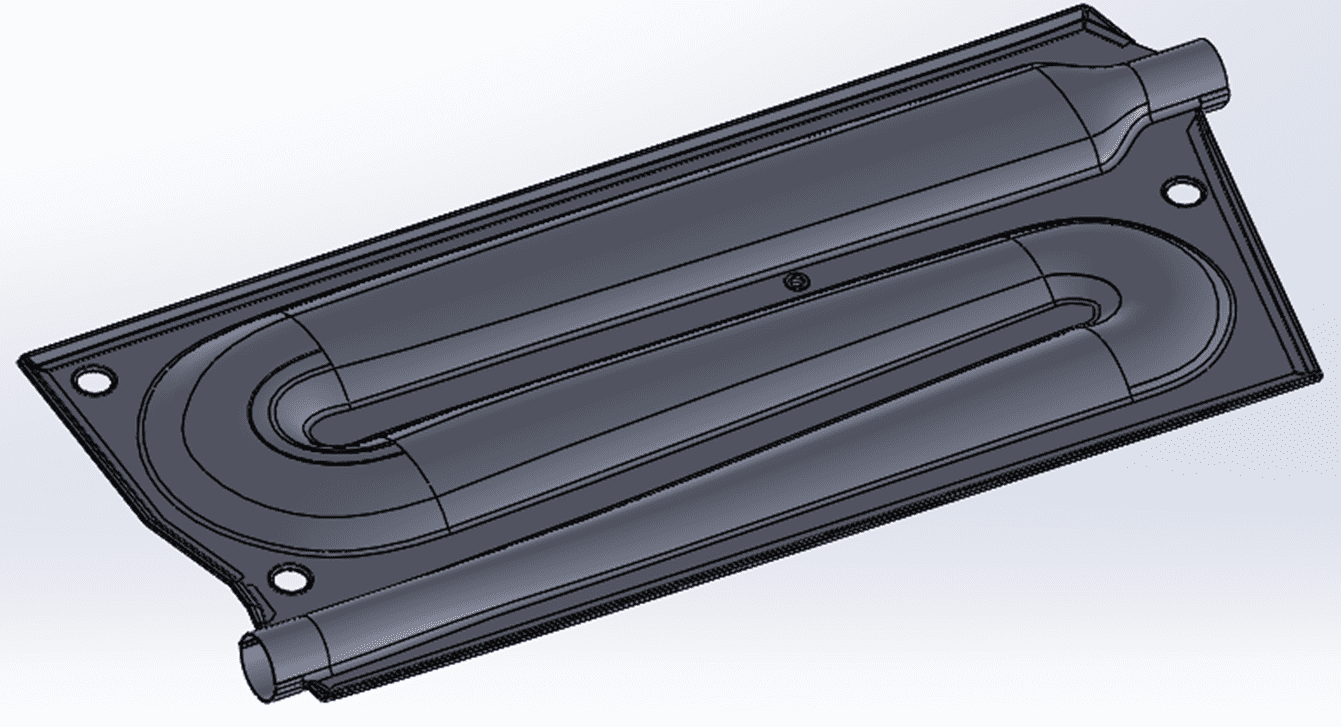

- Creation of 3D parametric model of Heat Exchanger from the physical part.

Why APA?

APA has a dedicated team to work on Reverse Engineering of Components with an exclusive lab set up for Probing, Scanning (3D Non-Contact), and measuring dimensions of various automotive and non-automotive components. We also have the capability to identify the chemical and mechanical properties of materials.

Reverse Engineering process:

Scanning:

- Prepare part by spraying white powder.

- Fix the part properly to scan.

- Get symmetry profile measurements before scanning the part.

PREPROCESSING:

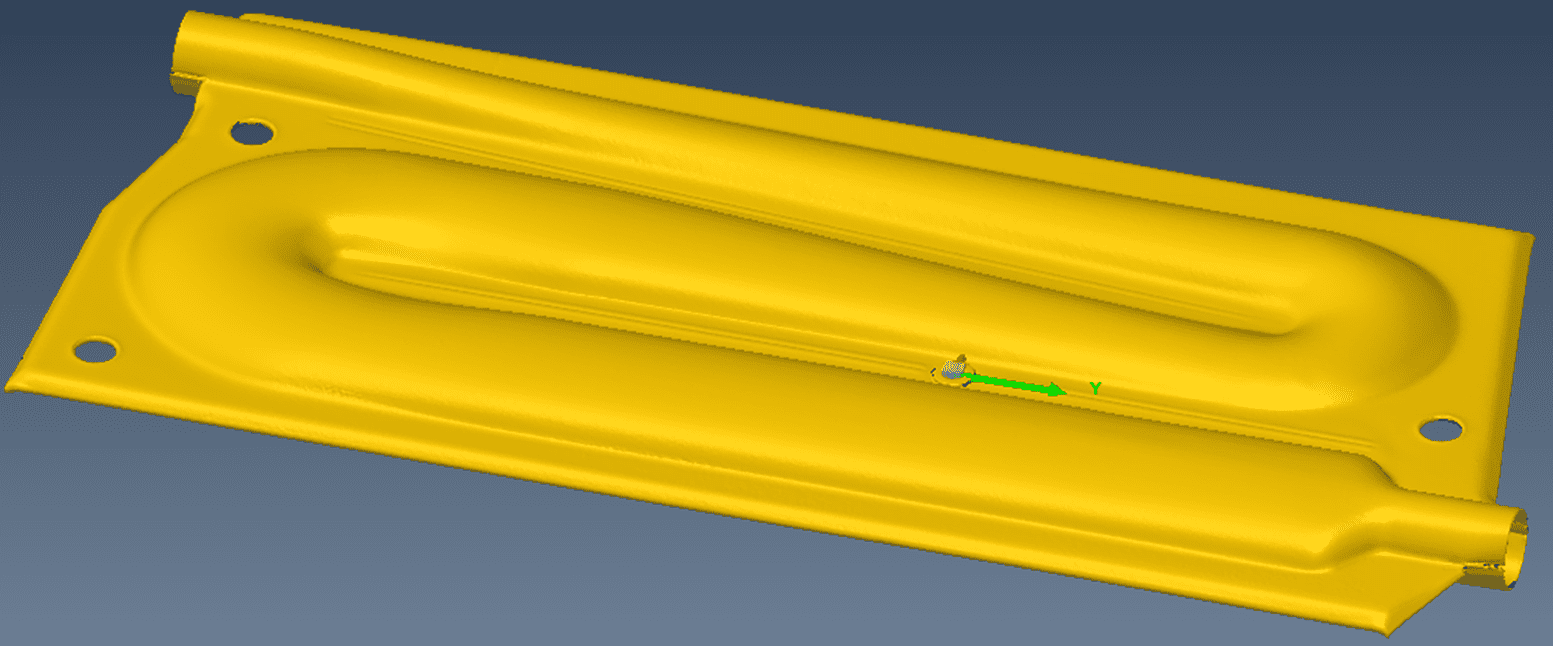

- Cleanup of Noise in the scan data and fill gaps.

- Align to coordinate system.

- Export as .stl format.

PARAMETRIC MODELING:

- Import .stl file.

- Extracted curvature profiles,Generate outer surface as per ASTM A963/A963M97standards.

- Build parametric model from scan data.

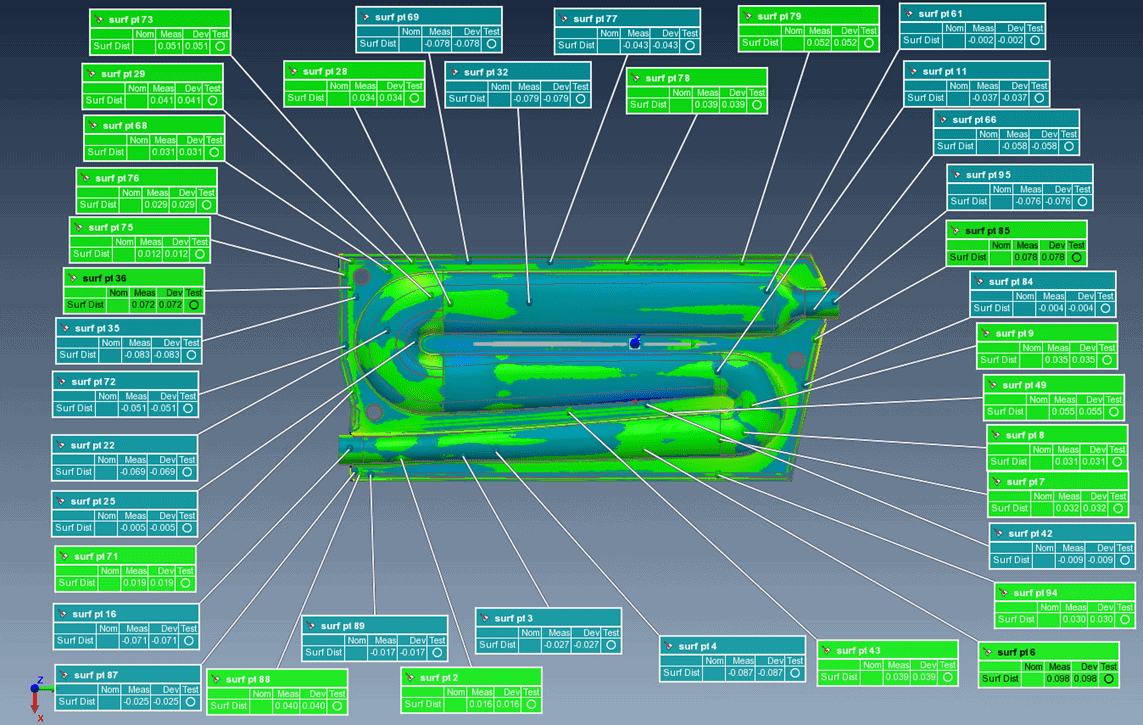

Quality Check:

- Overlay scanned data and 3D model.

- Identify deviations and geomertry correction.

- Generate comparison report.

Challenges Involved:

- Complexity of stamped features on the Heat Exchanger

- Extracting complex curves from the scanned data

- Constructing the geometry by carefully ignoring the surface Deformations

- Capturing the exact curvature of the involute profile to be used for CFD analysis

Value delivered:

- Delivered, high accuracy model achieving 98% match, higher than the client’s 95% requirements

- Developed 3D Model considering manufacturing feasibility, tooling and flexible for future design optimization.

If you would like to know more about this topic.