Client

Our client is a Casting parts manufacturer for Automotive companies across the globe.

Why APA Team?

APA has expertise in FEA driven optimization, taking weight out of the parts and yet meeting all the performance targets of the baseline design and hence adding significant value to Automotive component manufacturers.

Scope:

Weight optimization of Cast iron spring anchorage bracket under durability and extreme load cases and find the weight reduction potential upon conversion into Aluminium design.

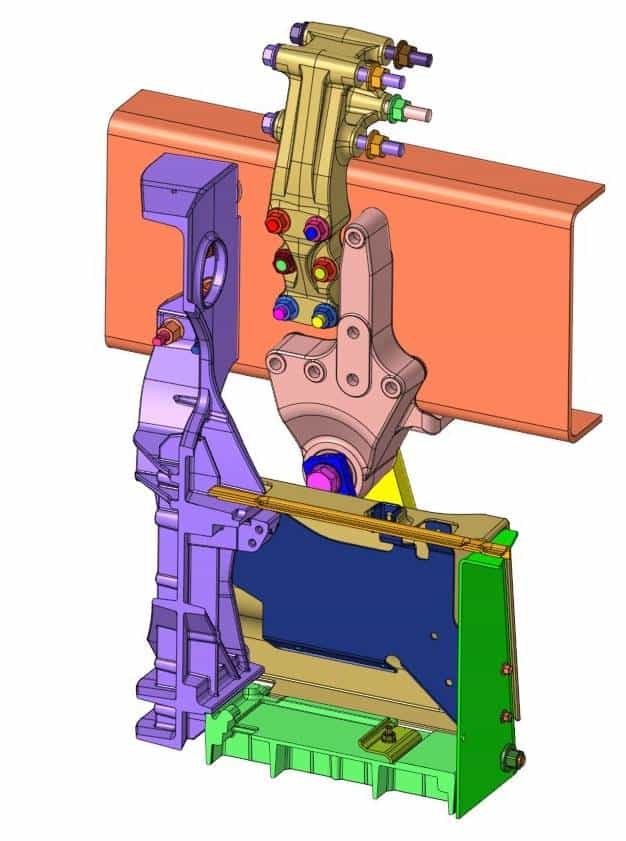

Suspension Assembly

Weight Optimization process:

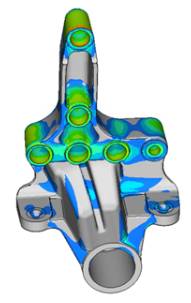

- Performing nonlinear static analysis including the detailed modelling of Bolt and Rivet connections with Material and contact nonlinearities consideration and a fine mesh resulting in a high-fidelity mathematical model.

- Topology optimization bringing out the load path and thus helping us to determine the potential areas of weight reduction.

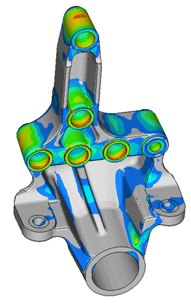

- Applying the manufacturing constraints for a GDC or PDC design and arriving at the optimized design.

- Verification of the optimized aluminium design to make sure having the same factor of safety as that of the Cast iron design.

Cast Iron

Aluminium Alloy Design

Value Delivered:

- Significant Weight reduction of 62 % from Cast iron to Aluminium alloy conversion.

- FEA driven optimization saving prototyping cost and accelerating the time to market.

If you would like to know more about this topic.