Client

Our client is a leading U.S. aftermarket manufacturer with a long history of delivering high-quality engine products. Their solutions are designed, engineered, and built to perform like original equipment while being competitively priced. They continue to serve the market with reliable products backed by strong technical expertise.

Scope

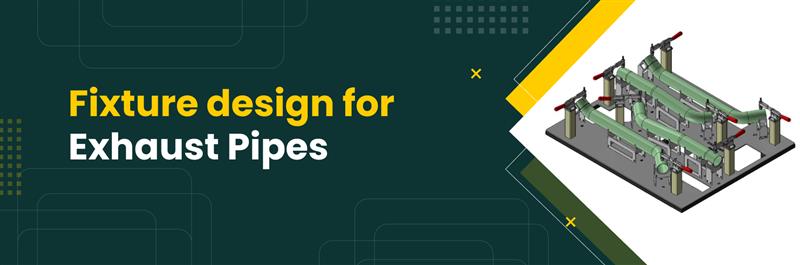

The project focused on designing a QC fixture for the exhaust assembly with fixture guidelines. The fixture layout ensured accurate pipe positioning, proper support, and repeatable inspection aligned with client QC requirements.

Why APA?

APA Engineering was selected because of our strong background in precision fixture design, detailed manufacturing-ready documentation, and integrated review processes. We leveraged our expertise to turn input from client into a turnkey fixture solution.

Design process

Input Gathering & review existing standards and aligning client inspection requirements.

Created the main fixture frame using box tubing and supporting bracing for flatness and rigidity.

Designed the base plate with laser-cut features: part-matching letters, weight-reduction, identification labels.

Developed saddles and inlet tube supports tight clearance to ensure accurate placement of the pipe.

Designed toggle clamp positions to secure pipe ends and hanger locations while leaving ends unobstructed.

Ensured all plate-mounted components were strictly vertical for repeatable inspection setup.

Prepared CAD files, DXFs, and part lists for manufacturing readiness.

Challenge Involved

● Maintaining tight clearance for saddle supports while ensuring ease of assembly and operator usability.

● Ensuring vertical alignment of all fixtures sub-assemblies to guarantee repeatable measurements and avoid fixture skew.

● Balancing fixture structural rigidity (avoiding deflection during inspection) with weight/handling considerations (plate thickness/weight-reduction cutouts).

● Design of toggles and clamp locations such that they did not interfere with pipe ends or inspection access.

Value delivered

APA Engineering have delivered a fully documented fixture package ready for immediate fabrication, improving inspection efficiency through precise pipe location, repeatable clamping, and reduced setup time. Clear part identification enhanced traceability, Thorough internal reviews ensured manufacturing and inspection readiness, reducing overall risk.

Need precision inspection fixtures for your assemblies?