Client:

Client is a global distributor of rotating electrical parts for Agricultural, Automotive, Light Truck, Marine and Power sports.

Requirement:

For the Lawnmower products, the client wanted a one stop solution for Re-Engineering the Spindle Assembly.

Why APA?

APA has 8 years of experience in Reverse & Re-Engineering of Spindle Assemblies, mechanical and electromechanical clutches and 20 years of experience in Sourcing parts and assemblies for US clients.

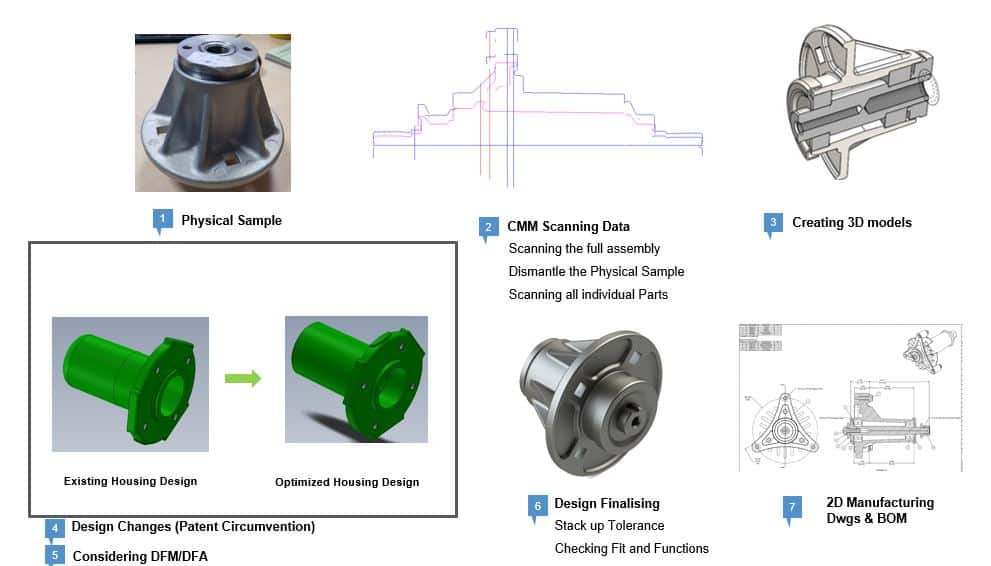

Re-Engineering Process:

Challenges Involved:

- Patent Study and Redesign without Patent breach.

- Optimizing the Fits &Tolerance to reduce manufacturing/machining cost

- Accurate feature extraction of all the internal parts, when scanning in Assembly Condition.

Value Delivered:

- Provided end to end support in Reverse Engineering, Re-engineering the Spindle Assembly, provided manufacturing drawings & with the help of our sourcing team, we identified suppliers to get this manufactured at very competitive price.

- Delivered in less than 2 weeks.

- Significant cost advantage to the client.

If you would like to know more about this topic.