Electric Vehicle Batteries: What Does Life Cycle Assessment Reveal?

With the rapid development of technology and the increasing awareness of climate change, electric vehicles (EVs) are emerging as a beacon of hope, a popular solution to reduce emissions from conventional fuel-powered vehicles. However, just like any other innovation, it is important to thoroughly examine the advantages and environmental impacts associated with their manufacturing and use. This is where Life Cycle Assessment (LCA) plays a critical role by providing a comprehensive understanding of the environmental impact of EV batteries, from their inception to disposal.

What Insights Does Understanding the Lifecycle of EV Batteries Offer?

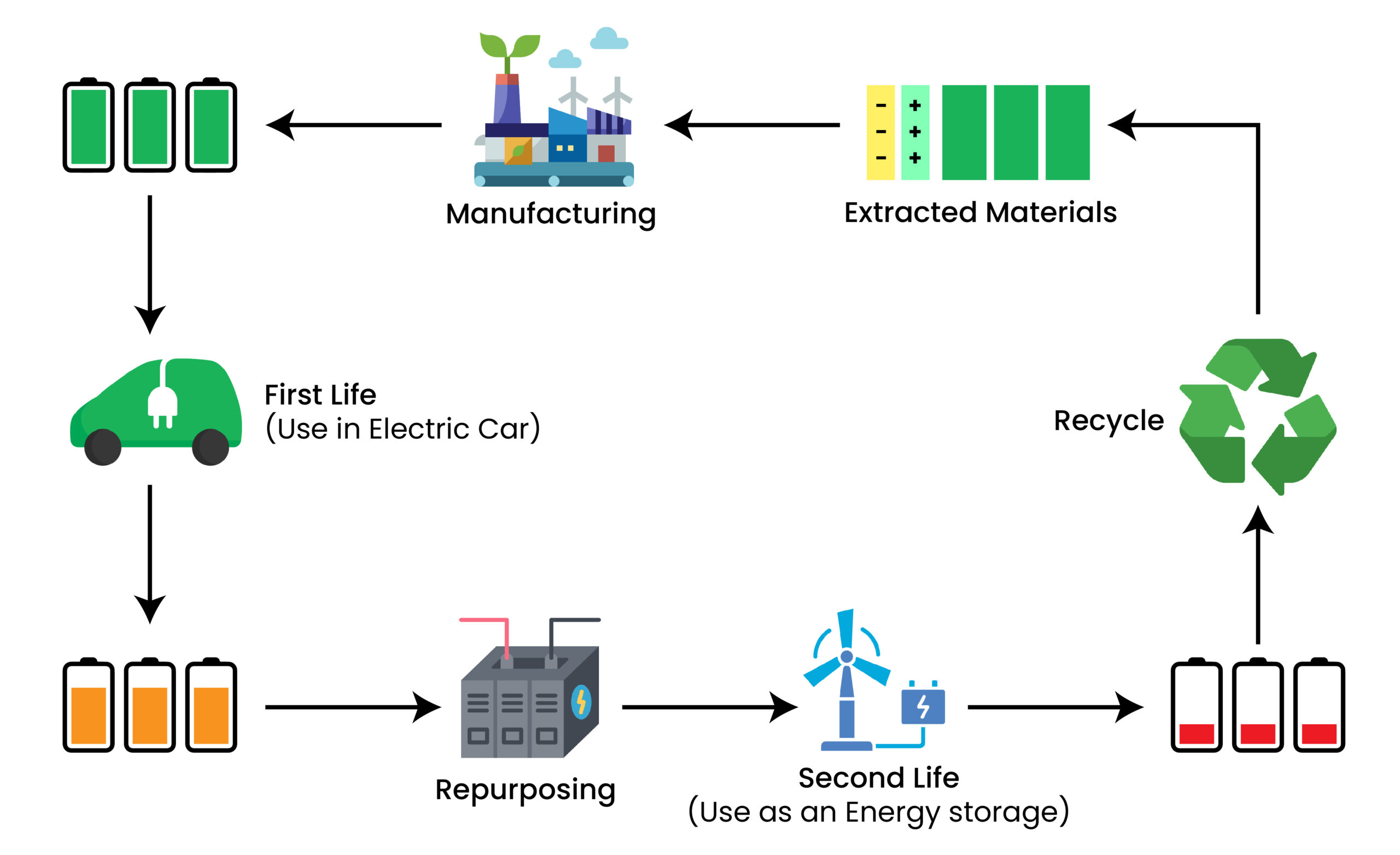

Electric vehicle batteries, typically lithium-ion batteries, undergo several stages, from raw material extraction to end-of-life disposal or recycling. Let's break down the lifecycle stages:

1. Raw Material Extraction and Processing: The journey begins with extracting raw materials like lithium, cobalt, nickel, and graphite, all critical minerals. Mining and processing these materials can have significant environmental consequences, including habitat destruction, water pollution, and carbon emissions.

2. Battery Manufacturing: Once the raw materials are procured, they undergo processing and are transformed into battery cells. This stage involves energy-intensive processes, such as electrode fabrication, electrolyte preparation, and cell assembly. These processes, while essential for battery production, also contribute significantly to greenhouse gas emissions and other pollutants. This highlights the importance of adopting sustainable practices in battery manufacturing.

3. Vehicle Integration and Use: The batteries are then integrated into electric vehicles, powering the vehicle's electric motor. During this phase, the environmental impact is in our hands. The choice of energy source used to charge the battery can make a significant difference. If renewable energy sources like solar or wind power are utilized, the environmental footprint decreases significantly compared to charging from fossil fuel-based grids.

4. End-of-Life Management: As batteries reach the end of their useful life in vehicles, it's crucial to ensure their proper recycling or disposal. Battery recycling involves the recovery of valuable materials like lithium, cobalt, and nickel for reuse in new batteries, contributing to a circular economy. However, if not managed correctly, improper disposal can lead to environmental contamination. This underscores the importance of responsible end-of-life management of batteries.

How Does Conducting an LCA on EV Batteries Illuminate Their Lifecycle?

Now that we understand the lifecycle stages, let's look into how LCA can be conducted to assess the environmental impact of electric vehicle batteries:

1. Goal and Scope Definition: Define the assessment's goal, such as comparing the environmental impact of different battery chemistries or identifying hotspots in the lifecycle. Determine the scope, including system boundaries, functional unit (e.g., per kilowatt-hour battery capacity), and allocation methods.

2. Life Cycle Inventory (LCI): Compile a comprehensive inventory of all inputs (e.g., raw materials, energy) and outputs (e.g., emissions, waste) associated with each lifecycle stage. This may involve gathering data from suppliers, manufacturers, and industry databases.

3. Life Cycle Impact Assessment (LCIA): Evaluate the potential environmental impacts of the inventory items using impact assessment methods. Common impact categories include global warming potential, acidification, eutrophication, and resource depletion.

4. Interpretation and Improvement: Interpret the LCA results to identify areas for improvement and inform decision-making. This could involve optimizing manufacturing processes, sourcing sustainable materials, or investing in renewable energy for charging infrastructure.

|

Example: Comparing Lithium-ion and Solid-state Batteries

Let's consider an example where we compare the environmental impact of lithium-ion batteries, the current standard in EVs, with emerging solid-state batteries:

1. Raw Material Extraction: Solid-state batteries may require fewer rare earth metals than lithium-ion batteries, potentially reducing the environmental impact of raw material extraction.

2. Manufacturing: Solid-state batteries could offer efficiency gains in manufacturing processes, leading to lower energy consumption and emissions than lithium-ion batteries.

3. Vehicle Integration and Use: Both battery types have similar impacts during the use phase, depending on the energy source used for charging.

4. End-of-Life Management: Solid-state batteries might be easier to recycle and could yield higher recycling rates than lithium-ion batteries, which often face challenges in recycling due to complex chemistries.

Simplified Example where lithium-ion battery is used in an Electric Vehicle

To provide a simplified example, let's calculate a basic Life Cycle Assessment (LCA) for a hypothetical lithium-ion battery used in an electric vehicle (EV). We will focus on two key stages: raw material extraction and battery manufacturing.

Assumptions:

1. Functional Unit: One kilowatt-hour (kWh) battery capacity.

2. System Boundary: Now consider the cradle-to-gate perspective, encompassing raw material extraction and battery manufacturing.

3. Impact Category: We will focus on the Global Warming Potential (GWP) as our impact category.

4. Data Sources: We'll use hypothetical data for illustrative purposes.

Life Cycle Inventory (LCI) Data:

1. Raw Material Extraction (Lithium, Cobalt, Nickel, Graphite):

• Lithium: 50 kg/kWh

• Cobalt: 5 kg/kWh

• Nickel: 30 kg/kWh

• Graphite: 20 kg/kWh

2. Battery Manufacturing:

• Energy Consumption: 150 kWh/kWh

• Emissions (CO2): 200 kg/kWh

Calculation:

1. Raw Material Extraction:

• Total raw material usage per kWh = Lithium + Cobalt + Nickel + Graphite = 105 kg/kWh

• Let's assume the GWP factor for raw material extraction is 10 kg CO2 equivalent per kg of material

• • GWP from raw material extraction per kWh = Total raw material usage * GWP factor = 105 kg/kWh * 10 kg CO2/kg = 1050 kg CO2 equivalent/kWh

2. Battery Manufacturing:

• GWP from energy consumption per kWh = Energy consumption * GWP factor = 150 kWh/kWh * 2 kg CO2/kWh = 300 kg CO2 equivalent/kWh

• GWP from emissions (CO2) per kWh = 200 kg CO2/kWh

Total GWP:

• Total GWP per kWh = GWP from raw material extraction + GWP from battery manufacturing = 1050 kg CO2 + 300 kg CO2 + 200 kg CO2 = 1550 kg CO2 equivalent/kWh

3. Interpretation:

In this simplified example, the total Global Warming Potential (GWP) associated with producing one kilowatt-hour (kWh) of lithium-ion battery capacity for an electric vehicle is calculated to be 1550 kg CO2 equivalent. This figure represents the environmental impact of the battery from raw material extraction through manufacturing.

Limitations:

• This example provides a basic overview and does not consider all factors involved in a comprehensive LCA.

• Actual data may vary based on factors such as location, technology advancements, and specific supply chains.

• Other impact categories beyond GWP should also be considered for a more comprehensive assessment.

Sustainable Decision-Making with LCA:

Life Cycle Assessment (LCA) calculations help quantify the environmental impacts of products and processes, providing valuable insights for decision-making toward more sustainable practices. While this example offers a simplified illustration, conducting LCAs using accurate data and methodologies enables stakeholders to make informed choices to reduce their ecological footprint and strive toward a more environmentally responsible future. By comprehensively assessing the life cycle of products and processes, LCA empowers stakeholders to identify areas for improvement, innovate towards greener alternatives, and ultimately contribute to a healthier planet for future generations.

Reach out to our regulation experts on chemical and product regulatory compliances