What is Life Cycle Assessment (LCA)?

Life Cycle Assessment (LCA) is a systematic method for evaluating the environmental impacts of a product, process, or service throughout its entire life cycle. This encompasses all stages, from the extraction of raw materials, through production, distribution, use, and end-of-life disposal or recycling. LCA considers various environmental aspects such as resource use, energy consumption, air, water, soil emissions, and waste generation. The aim is to comprehensively understand the environmental burdens associated with a product or activity and identify improvement opportunities to minimize these impacts.

Our previous blog post briefly overviews the four main steps in conducting a Life Cycle Assessment (LCA). Below is a more detailed discussion for your reference.

1. Goal and Scope Definition: During this phase, key activities are performed to define the assessment's framework and objectives. The study's purpose and details of the product system are established before data collection, defining the goal and scope.

a. Defining the purpose: The first step is to clearly define the purpose of the LCA, including identifying why the assessment is being conducted and what specific questions it aims to answer.

b. Defining the scope: First, it is important to define the system boundaries to decide which processes and activities will be considered in the assessment and which ones will be excluded. Then, the next step is to define the functional unit, which is a measurable unit used to compare the environmental performance of different products or systems. For instance, it could be the amount of energy produced from one Liter of biofuel.

c. Setting up boundaries: Temporal boundaries specify the time period during which the assessment will be conducted, and spatial boundaries define the study's geographical boundaries. For example, the assessment may focus on a specific region in a global organization.

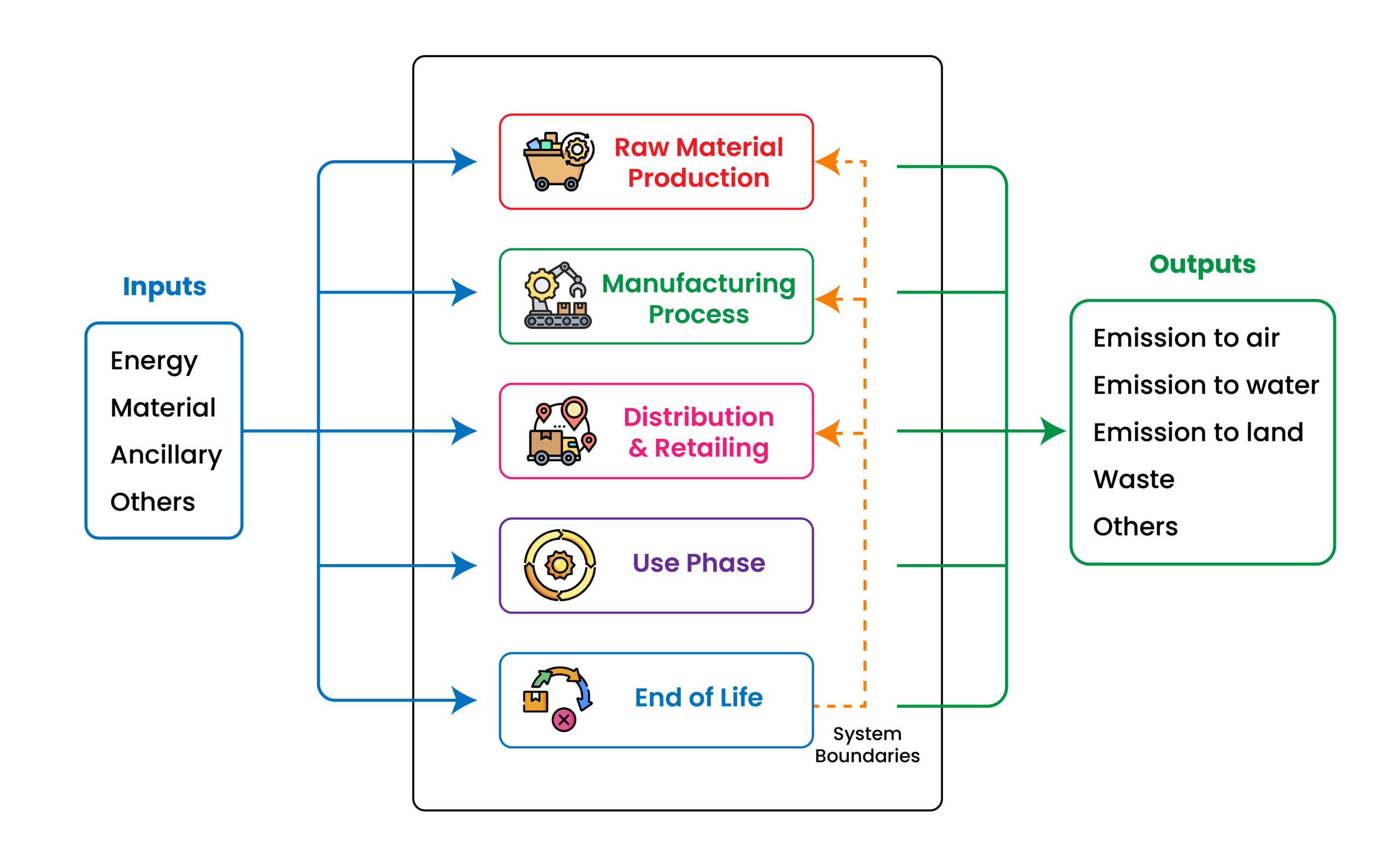

2. Life cycle Inventory Analysis: This phase involves gathering data on all inputs and outputs associated with the product, process, or system being evaluated. During this phase, elements like energy requirements, raw material requirements, emissions to air, land, water, wastes, and any other form of release into the environment must be quantified. This allows for an accurate assessment of the environmental impacts throughout the life cycle. The LCI analysis has four significant steps.

|

Figure 1 Reference: Lifecycle inventory phase (modified from Bachmann, Hidalgo & Bricout)

a. Mapping the inputs and outputs to the process or system within the defined system boundary using a flow diagram. The flow diagram helps to illustrate the flow of materials, energy, and other resources throughout the life cycle stages.

b. The development of a data collection methodology involves establishing a systematic approach for gathering data on the inputs and outputs associated with the product, process, or system being assessed.

c. Collection of the relevant data: Comprehensive data collection is essential when assessing a product's environmental impact throughout its life cycle, from raw materials extraction to disposal. Primary data is directly obtained from operational facilities such as energy consumption, material usage, emissions, waste generation, production processes, transportation distances, and other relevant parameters. On the other hand, secondary data, which provide environmental impacts of materials, processes, energy sources, and transportation modes commonly used in the product's life cycle, are collected from external sources like databases (such as Ecoinvent, GaBi, ELCD) or industrial reports like Material Safety Data Sheet (MSDS) and other published sources from specific operations and processes. These secondary data supplement the primary data obtained to comprehensively analyze the product's environmental impact.

d. Evaluation and reporting of results: After collecting the data needed for a Life Cycle Inventory (LCI) study, it's important to evaluate the accuracy and reliability of the data. Any gaps or missing data should be addressed using estimation techniques or sensitivity analysis. Moreover, it's crucial to assess the relevance of the data collected to the specific goals and scope of the study. Irrelevant or redundant data should be excluded to focus on key parameters and environmental impacts. Also, it's essential to maintain detailed documentation to facilitate peer review, reproducibility, and transparency of the LCI results. Documenting data sources using formats like The International Reference Life Cycle Data System (ILCD), ISO 14040 / 14044, and The Product Environmental Footprint (PEF) ensures the credibility and reliability of the LCI analysis.

3. Life Cycle Impact Assessment (LCIA): LCIA stands for Life Cycle Impact Assessment, which involves the evaluation and quantification of environmental impacts of a product, process, or service throughout its life cycle. This assessment is based on the Life Cycle Inventory (LCI) data. For instance, let us say that a product is manufactured using a certain amount of natural gas consumed during the production process. This is recorded in the inventory during the LCI phase. In the LCIA phase, the impact of global warming caused by natural gas combustion is calculated. However, it's important to note that LCIA is not used to determine actual impacts. Instead, it links the data gathered from LCI to impact categories and determines the relative magnitude of contribution to the impact category. Here are the key steps in LCIA.

|

Figure 2 Reference: DIN Deutsches Institut fur Normang

a. Selecting the relevant impact categories for the assessment. Impact categories refer to the specific environmental concerns or areas of impact that are evaluated and quantified during the Impact Assessment phase. The selection of impact categories may vary depending on the assessment's goals, scope, and context. Some examples are climate change, acidification, eutrophication, human health, and biodiversity.

b. Classification: The data gathered from the inventory analysis is assigned to the impact categories. For example, greenhouse gas emissions during combustion or manufacturing processes will be assigned to climate change.

c. Characterization: During this step, the inventory data is converted into impact scores for each impact category. The inventory data includes raw emissions and resource use. The process involves the application of characterization factors that measure the potential environmental effects of the emissions and resource consumption in terms of their contribution to each impact category. Let's see how Characterization works for the impact category Global Warming Potential (GWP) for a case where the inventory data show that a specific manufacturing process emits 1000 kg of methane (CH4) per year. Based on the data provided as a reference by the IPCC's fifth assessment report, the GWP of methane over a decade is 28. GWP impact = 1000 kg CH4 * 28 = 28,000 kg CO2-equivalent. This means that the environmental impact of emitting 1000 kg of methane is equivalent to emitting 28,000 kg of carbon dioxide in terms of global warming potential over a 100-year period. Thus, characterization factors are applied to quantify the potential environmental impacts.

ISO 14042, which provides the guidelines and requirements for conducting Life Cycle Impact Assessment (LCIA), considers classification and characterization key elements of LCIA, while Normalization, Grouping, and Weighting are optional.

d. Normalization: This provides a basis for comparing the relative significance of different impact categories.

e. Grouping: Ranking the impact indicators

f. Weighting: Assign relative importance or priority to different impact categories based on their values and preferences

LCIA is performed during standard methodologies are used to quantify and evaluate the potential environmental impacts identified during the LCI phase of an LCA. Some widely adopted methodologies used are the ReCiPe ((Relevance, Endpoint, and Damage) Method, CML (Center of Environmental Science, Leiden University) Method, IMPACT 2002+, TRACI, and Product Environmental Footprint (PEF).

4. Interpretation: Life cycle interpretation is the last step of the LCA study, which involves analyzing the results from the life cycle impact assessment.

a. Goal Achievement The initial stage of Interpretation is to assess whether the study's predefined objectives and scope have been met. This entails evaluating whether the LCA study has furnished the intended understanding, resolved the research queries, and addressed the assessment aims.

b. Identification of Hotspots: Hotspots refer to specific areas within a product or process's life cycle that cause significant environmental impacts. The results of the Impact Assessment phase must be analyzed to identify these hotspots. These hotspots may include stages with high emissions, resource consumption, or environmental damage. The production of steel involves a process known as the blast furnace process, which is commonly used in integrated steelmaking. However, this process requires a lot of energy and heavily relies on the combustion of fossil fuels like coal and coke. This results in a significant amount of energy consumption, which can be considered a hotspot. To reduce the environmental impact of this hotspot, manufacturers can opt for alternative production processes such as Electric-Arc-Furnace.

c. Sensitivity Analysis: Sensitivity analysis is conducted to assess the robustness of the LCA results and the influence of uncertainties and assumptions on the outcomes. This involves varying input parameters, assumptions, or methodologies to understand how changes affect the results and conclusions of the LCA study.

d. General Analysis: Interpretation often involves comparing the environmental performance of different products, processes, or scenarios. This may include comparing alternative designs, materials, technologies, or management practices to identify the most environmentally preferable options. For example, reducing greenhouse gas emissions may increase water consumption for Hydropower generation, highlighting the need to consider multiple impact categories simultaneously and balance competing environmental objectives.

e. Recommendations: After conducting a Life Cycle Assessment (LCA), Interpretation can offer decision support by providing recommendations for enhancing the environmental performance of the product, process, or system being examined. These recommendations may encompass suggestions for optimization, mitigation strategies, or alternative options that can help minimize environmental impacts.

f. Communication and Reporting for further feedback and improvement: Interpretation is the process of conveying the findings of a Life Cycle Assessment (LCA) study to stakeholders, decision-makers, and other relevant parties. This can be done through the preparation of LCA reports, presentations, or visualizations that communicate the results, implications, and recommendations of the study. The feedback received from decision-makers can help improve the sustainability of product life cycles through continuous improvement.

Our next blog will feature a case study of an actual LCA, following our explanation of how Life Cycle Assessment is conducted.

Reference: Science Direct and US EPA, EU LCA

Reach out to our regulation experts on chemical and product regulatory compliances