Client:

Casting parts manufacturer supplying to Major OEMs.

Scope:

To increase the capacity of the plant from the current perday capacity of 3 Tonnes to 5 Tonnes, by looking at layout optimization, automation of critical processes, process study and elimination of non-value added activities.

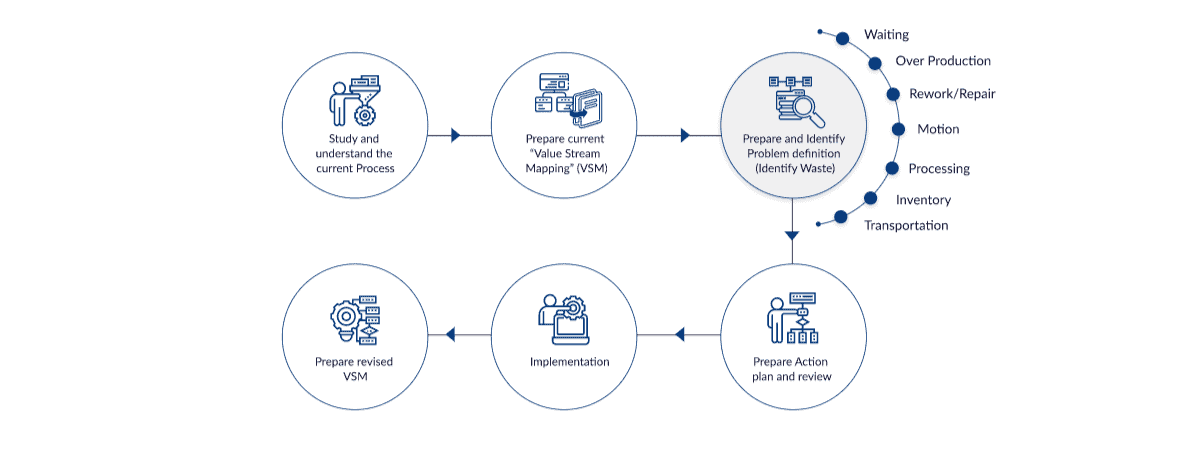

Visual Representation of Our Value Delivered

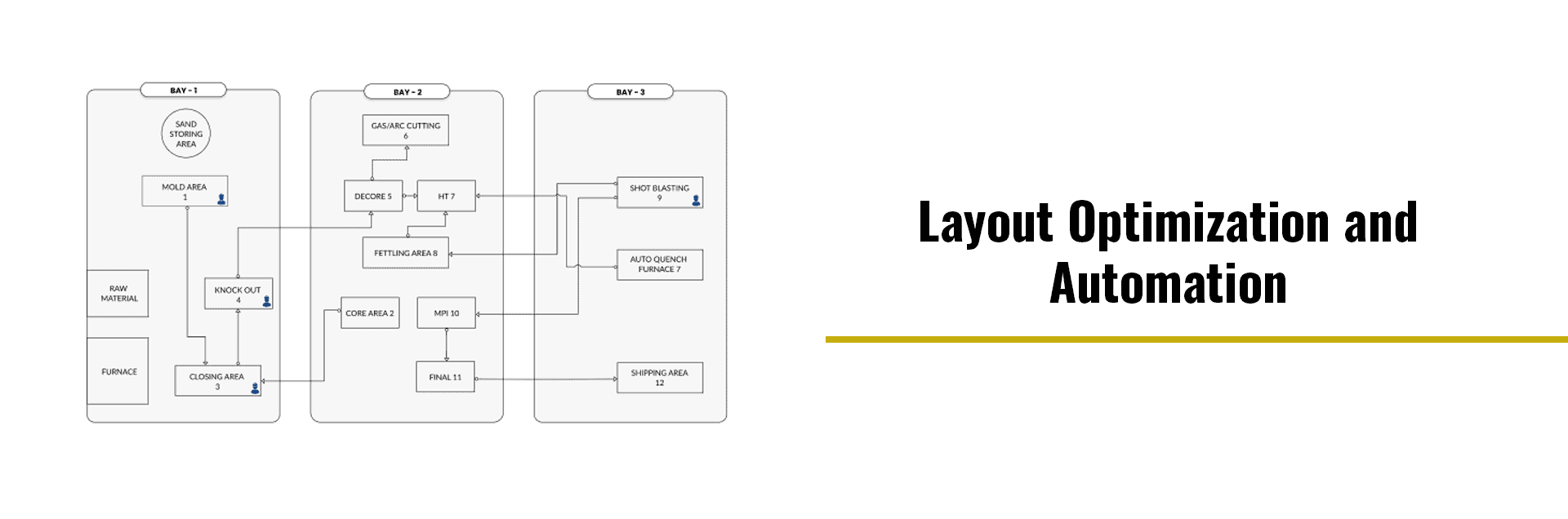

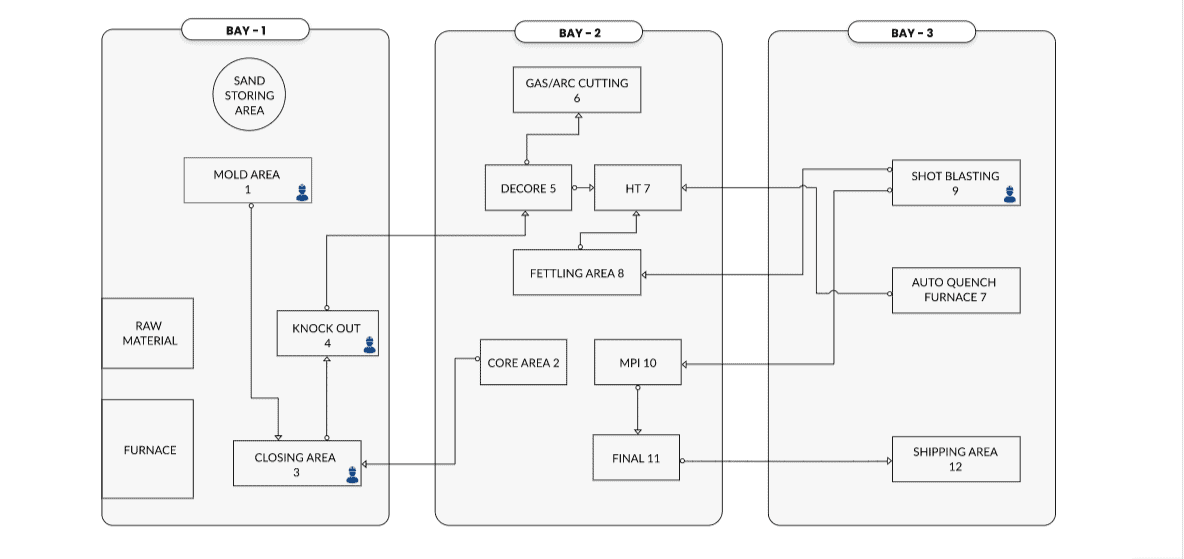

existing Layout

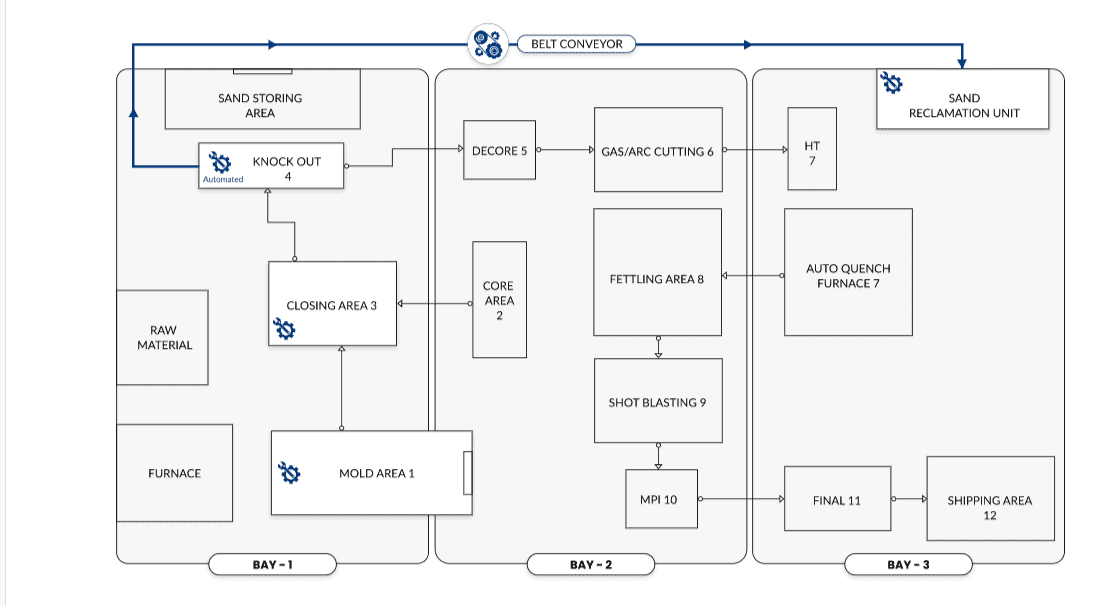

Proposed Layout

Existing process

- Sand & Sodium Silicate mixing is done manually

- The mixture is carried to the moulding area manually

- 3 skilled, 7 semi-skilled & 3 unskilled manpower

Proposed process

- Automatic mixing and tansfer of mixed sand to the moulding area with a shooter arrangement

- Arrangement for storing fresh sand in a hooper

Advantages

- Consistency of sand & Sodium silicate mixing ensured at the point-of-use

- 7 semi-skilled and 3 unskilled operators moved out

Existing process

- After curing the molds (after they received the molten metal) for 24 hours, the molds are transferred to the knock-out area manually.

- The metal boxes are removed by hammering them.

- The metal and the sand are separated by knocking them manually

Proposed process

- The molds are transferred to the knock-out area by the conveyor system and placed on a knock-out/shake-out table. This is a vibrating table.

- Due to the vibration, the metal box is easily separated from the mold. Also the solidified cast part is separated from the sand mold.

Advantages

- The 24 hours waiting period is eliminated

- Eleminated the manpower due to the automation

Existing process

- The sand lumps are carried manually to a sand crushing area.

- The sand lumps are crushed by moving a heavy roller on them

- A potion (usually 20%) of the used sand is then mixed with sodium silicate and reused as packing sand inside the mold.

Proposed process

- The sand lumps are transferred to the sand crusher using a conveyor arrangement.

- The crushed sand is separated and stored in overhead tanks.

- As an when required, this crushed sand is mixed with sodium silicate and transferred to the mold line (to be used as a packing sand)

Advantages

- Improved house keeping

- Eleminated the manpower due to the automation

Existing process

- It was difficult to move the "molded parts" to the "closing area" via "knockout".

- Two overhead cranes were needed. One for handling the furnace and another one for moving the molds.

Proposed process

- Kept the mold area nearby furnace.

Advantages

- Eleminated the necessity of two overhead cranes and used the same overhead crane for both

Existing process

- There was a criss-cross movement in material handling

Proposed process

- Rotated the furnace orientation

- Introduced sand reclamation equipment and transferred the sand lumps from the knockout stage using a belt conveyor

- Placed all the stations as per the sequence of operations.

Advantages

- The material handling time was reduced drastically.

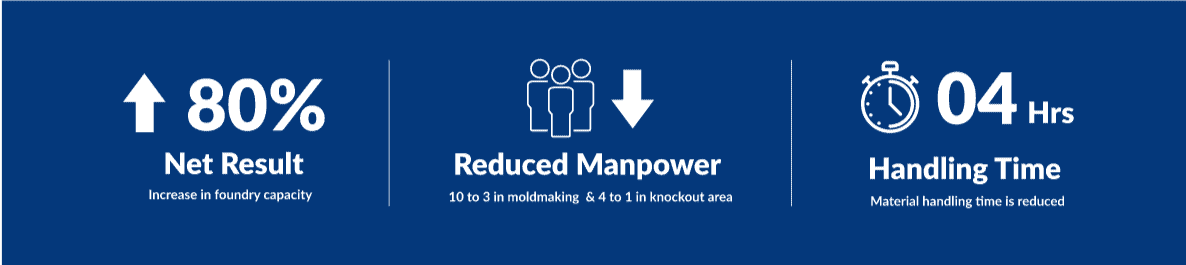

Value delivered:

- Reduced the manpower from 10 to 3 in mold making area and from 4 to 1 in knock out area.

- Removed the criss-cross movements. So material handling time was reduced.

- Used the same overhead crane for both furnace and closing area.

- Better utilization of layout to accommodate more equipment.

The Benefit:

Overall, the net result was a 80% increase in foundry capacity, along with improved interdivisional efficiency, communication and cooperation.

If you would like to know more about this topic.