Client:

Our client is a one of the largest auto components manufacturer and supplier of aluminium die castings to automotive and non-automotive sectors.

Why APA Team?

APA has expertise in designing and validating fixtures for manufacturing process in automotive industry.

Scope:

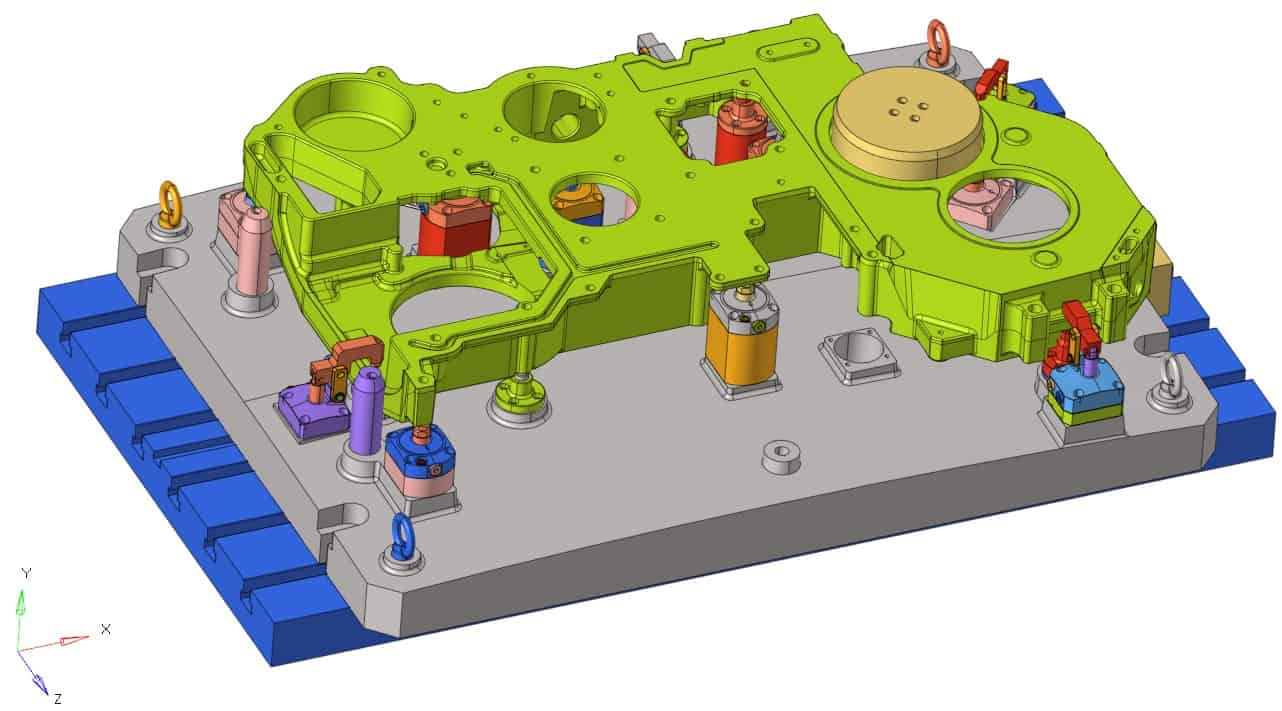

Simulation process for Gear Housing Fixture:

- 1. Performing static analysis on the Gear Housing constrained using fixture for the milling load applied at 45 deg.

- 2. Gear Housing is placed on the hydraulic pistons of the fixture.

- 3. Clamping load due to the piston are applied on the gear housing locations, in vertical downward directions and the bottom of the fixture is constrained in all directions.

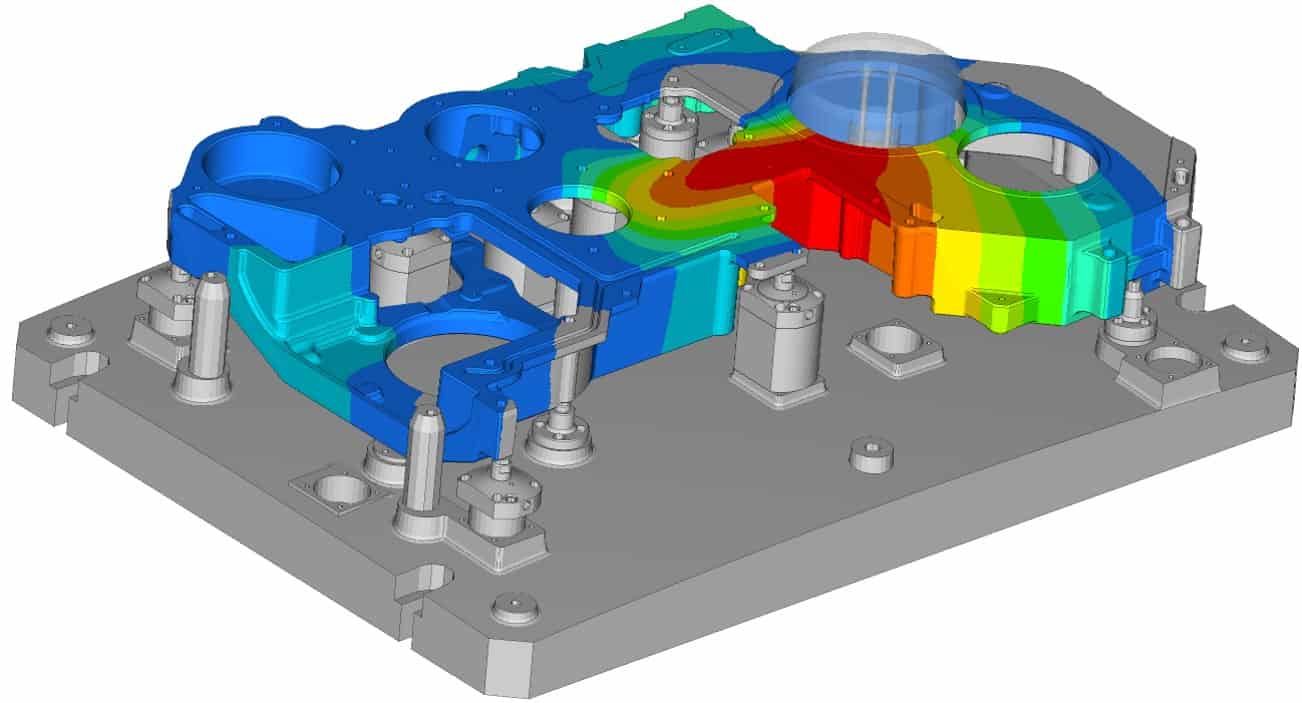

- 4. Due to the applied milling load, excessive vertical deflections were observed on the centre region of the gear housing.

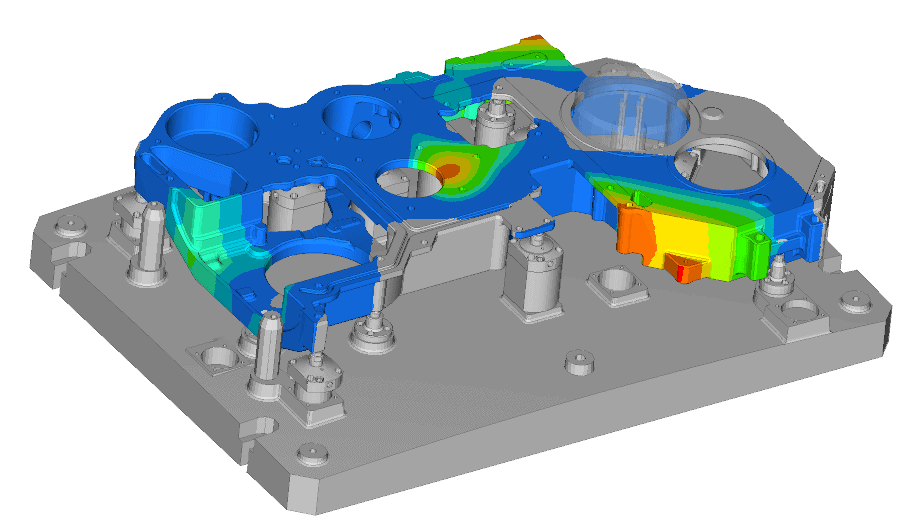

- 5. To reduce the deflection, fixture was modified with an addition of hydraulic piston support at the critical location.

Baseline Design – Deflection Plot

Improved Design – Deflection Plot

Value Delivered:

- 1. Recommended design modification and also performed analysis to confirm that the modified design meeting the performance requirements, thus giving confidence to the client to finalize the design.

- 2. FEA driven development approach thus significantly reduces the time and cost compared to conventional prototype development and testing process.

If you would like to know more about this topic.