Why Us?

Product Design

Born out of rough ideas, product designing requires enhancements like mechanical part design, feasibility study, material selection, manufacturability, etc. through proper planning for a full-fledged part or product as the desired output.

Concept Design

We understand that a product’s Concept Design effectiveness is realized and valued when it serves as base for structuring a product with clear view towards the end goal. Every project is planned meticulously and given utmost attention by APA.

Design FMEA

Design FMEA plays a huge role in creating reliable products. Being an indispensable part of the Advanced Product Quality Plan (APQP) process, we at APA strive to follow and maintain the process flow.

Design with DFM & DFA

DFM and DFA are implemented for the reduction in overall complexities, manufacturing costs, and simplifying Assembly Process based on appropriate material selection. Our strength arises from our experience in product establishment.

Drawings, BOM and GD & T

Precise product manufacturing requires the right medium for processing. APAs mastery in detailing, BOM creation, and GD & T gives an assurance in generating and delivering the accurate output.

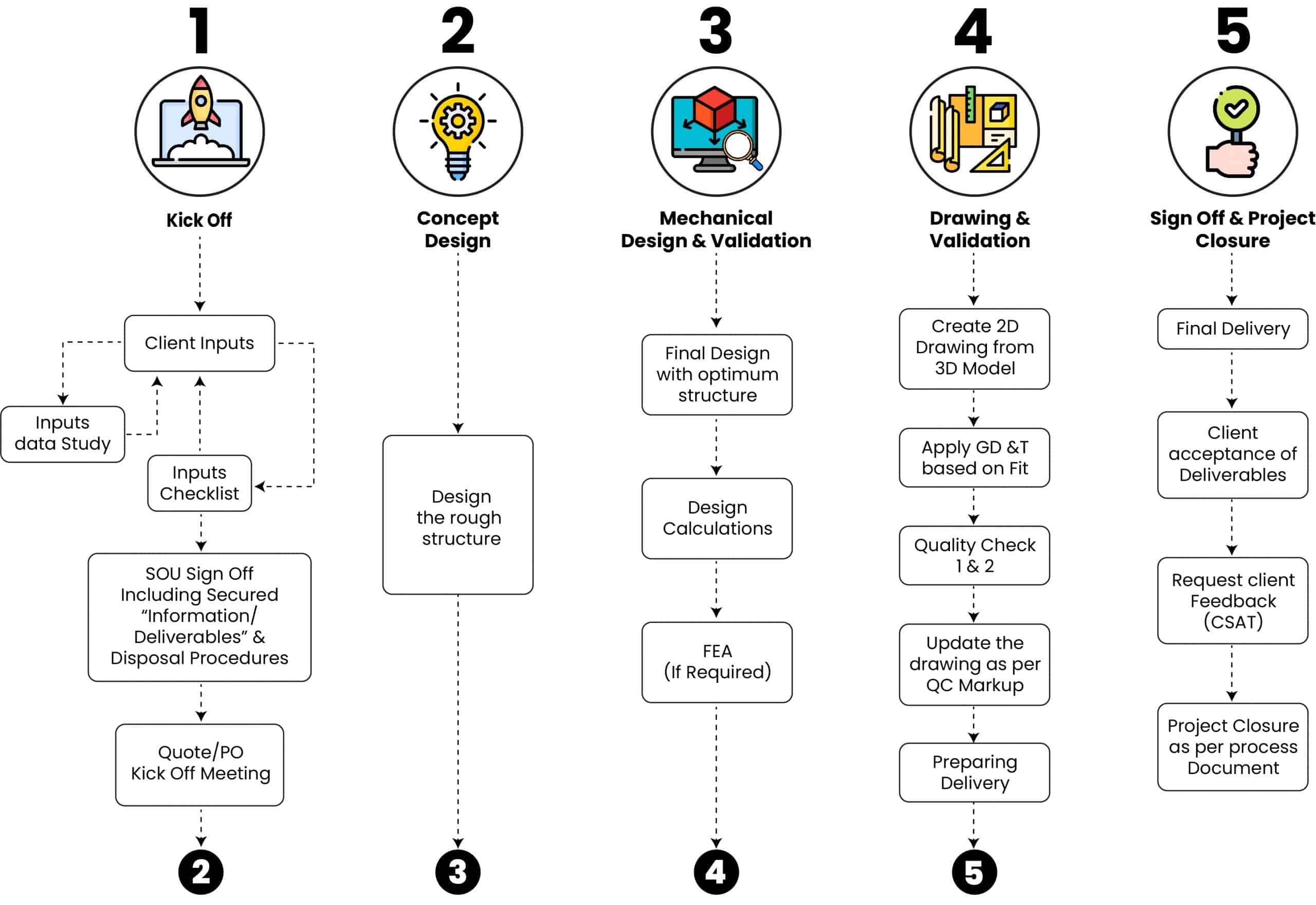

Flow Chart

Talk to our expert